Metallurgical Abstracts on Light Metals and Alloys vol.55

Interface Strengthening of α–Mg/C14–Mg2Ca Eutectic Alloy

Satoshi Araki*, Koji Oishi* and Yoshihiro Terada*

*Department of Materials Science and Engineering, Tokyo Institute of Technology

[Published in Metals, Vol. 11 (2021), 1913]

https://doi.org/10.3390/met11121913

E-mail: terada.y.ab[at]m.titech.ac.jp

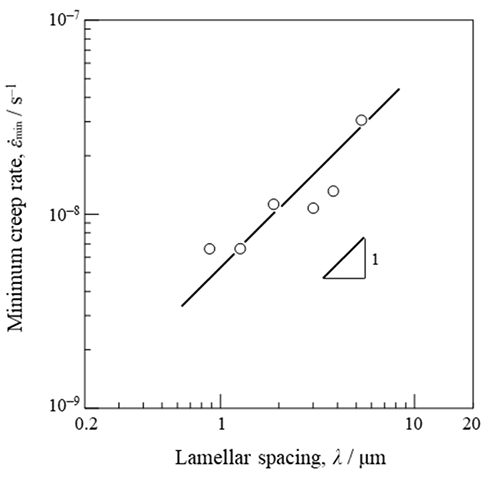

Key Words: magnesium alloy, eutectic, microstructure, creep, dislocation

This study investigates the effect of the α/C14 interface on the creep strength of α–Mg/C14–Mg2Ca eutectic alloy at 473 K under a stress of 40 MPa. The α/C14 interface is composed of terraces and steps, with terraces parallel to the (-1101)α pyramidal plane of the α-Mg lamellae and to the (11-20)C14 columnar plane of the C14–Mg2Ca lamellae. The creep curves of the alloy exhibit three stages: a normal transient creep stage, a minimum creep rate stage, and an accelerating stage. The minimum creep rate is proportional to the lamellar spacing, indicating that the α/C14 lamellar interface plays a creep-strengthening role. In the high-resolution transmission electron microscopy image captured of the specimen after the creep test, <a> dislocations can be mainly seen within the soft α-Mg lamellae, and they are randomly distributed at the α/C14 interface. In contrast, dislocations are rarely introduced in the hard C14–Mg2 lamellae. It is deduced that the α/C14 interface presents a barrier to dislocation gliding within the α-Mg lamellae and does not help rearrange the dislocations.

Fig. Plots of minimum creep rate vs. lamellar spacing for the α–Mg/C14–Mg2Ca eutectic alloy, where the creep tests were carried out at 473 K under a stress of 40 MPa.