Metallurgical Abstracts on Light Metals and Alloys vol.55

Formation Mechanism of Tempering-Induced Martensite in Ti–10Mo–7Al Alloy

Yoshito Takemoto1, Mikiko Yasuno1, Masaki Ikemoto1, Hiroyuki Ando2 and Ichiro Shimizu3

1Graduate School of Natural Science and Technology, Okayama University

2Faculty of Engineering, Okayama University

3Faculty of Engineering, Okayama University of Science

[Published in Materials Transactions, Vol. 63, (2022), pp. 489–496]

https://doi.org/10.2320/matertrans.MT-M2021214

E-mail: takemoto[at]mech.okayama-u.ac.jp

Key Words: α"-martensite, Thermal stress, Tempering, In situ observation, Reverse transformation

The formation mechanism of α"–martensite (α"Mt) induced by tempering at 450–550 °C for a short time was investigated using Ti–10Mo–7Al alloy. The solution treated and quenched (STQ) sample was composed of β phase and a small amount of α"Mq, and a large amount of α"Mt was generated by rapid tempering at 550 °C for 3 s using a salt bath. However, α"Mt was completely transformed into a single β phase by aging at 200 °C for 3 min. Reversibility was observed between the α"Mt transformation and the β reverse transformation. In–situ high–temperature X–ray diffraction measurements revealed that α"Mq → β reverse transformation occurred at 200 °C and that a thermally activated α"iso was generated at 450 °C due to the slow heating rate. In–situ optical microscopic observation of STQ sample with rapid lamp heating revealed that α"Mt was formed during heating process. However, α"Mt did not generate under following conditions; that is, a slow heating rate, thin sample plate, and a small temperature difference until tempering by preheating. On the other hand, rapid tempering using thick plate from liquid nitrogen (–196 °C) to 250 °C was performed to ensure a sufficient temperature difference, but α"Mt was not generated at all.

From the cross–sectional observation of the STQ plate, it was found that α"Mq was hardly formed on the surface of the sample, but was formed abundantly inside the sample. On the other hand, in the rapidly tempered plate, a large amount of α"Mt was distributed in the surface layer than inside sample. These results suggest that the thermal compressive stress induced by rapid heat treatment contributes to the formation of α"M.

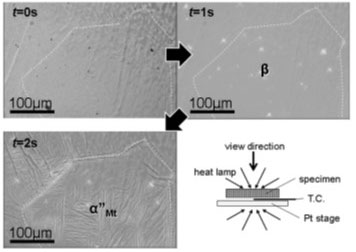

In–situ observation of microstructural evolution of 10MoA due to rapid lamp heating. Acicular martensite appeared within 2 s after the start of heating, indicating that martensite is formed during heating rather than cooling.