Metallurgical Abstracts on Light Metals and Alloys vol.55

Fracture dominant in friction stir spot welded joint between 6061 aluminum alloy and galvannealed steel based on microscale tensile testing

Tomoki Matsuda*, Toshiya Ogaki*, Kotaro Hayashi*, Chihiro Iwamoto**, Takashi Nozawa***, Mitsuru Ohata* and Akio Hirose*

*Division of Materials and Manufacturing Science, Graduate School of Engineering, Osaka University

**Department of Materials Science and Engineering, Ibaraki University

***National Institutes for Quantum Science and Technology (QST)

[Published in Materials & Design, Vol. 213 (2022), 110344]

https://doi.org/10.1016/j.matdes.2021.110344

E-mail: t-matsu[at]mapse.eng.osaka-u.ac.jp

Key Words: Microscale tensile testing, Fracture behavior, Intermetallic compound, Friction stir spot welding, Interface structure, Dissimilar joining

The macroscale mechanical properties of dissimilar joints are generally influenced by the fracture behavior of joint interface. However, little is known about the dominant factor for the joint properties related with both macroscale fracture behavior and microscale interfacial properties. Herein, microscale tensile testing of the joint interface was coupled with the macroscale fracture evaluation to elucidate the dominant factor of strength in dissimilar joints between 6061 aluminum alloy and high tensile strength galvannealed steel via friction stir spot welding (FSSW). Microstructural analyses revealed the characteristic formation of interfacial microstructure accompanied by friction and Zn discharge during the FSSW process. Microscale tensile testing was performed on the specimen on which the pre-notch was introduced to induce local fracture at the intended position on the joint interface. Results showed the presence of the weakest interface attributed to initial joining defects formed by Zn concentration at the outer area, which were consistent with the outside of the crack arresting area confirmed by macroscale evaluation. These results indicated that the joint strength of dissimilar joints between 6061 aluminum alloy and galvannealed steel is dominated by the local strength of the joining area without defects and suggested a process design for improving dissimilar joints.

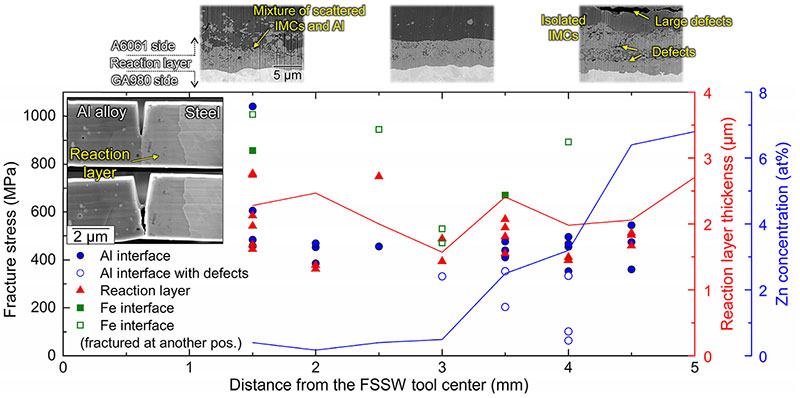

Distributions of tensile strength obtained using microscale tensile test as a function of distance from the tool center for the steel/aluminum alloy interface.