Metallurgical Abstracts on Light Metals and Alloys vol.55

Effects of Repeated Accumulative Roll Bonding Cycles on Microstructural Characteristics and Tensile Behaviors of Al2O3 Particle Reinforced Aluminum-Matrix Composites

Wenchuang Liu*, Yujiao Ke**, Kenjiro Sugio*, Zixiang Qiu**, Wenquan Li, Ying Guo*, Xingang Liu*, Gen Sasaki*

*Graduate School of Advanced Science and Engineering, Hiroshima University

**College of Mechanical Engineering, Yanshan University

[Published in Materials Letters Vol.320 (2022), 132386]

https://doi.org/10.1016/j.matlet.2022.132386

E-mail: gen[at]hiroshima-u.ac.jp

Key Words: particle reinforced aluminum-matrix composites, accumulative roll bonding (ARB), microstructure, machine learning, tensile properties

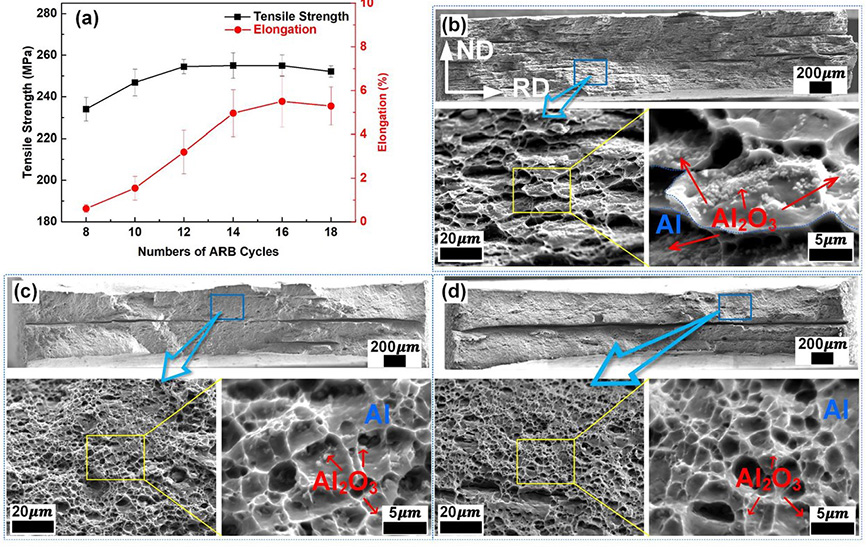

The effects of repeated accumulative roll bonding (ARB) cycles on reinforcement phase features, matrix microstructure, and composite tensile behavior evolution were investigated by microscopy, machine learning, tensile testing, and fracture surface observation. The results showed that with increasing ARB cycles, the reinforcement particles decohered and their distribution uniformity improved. Meanwhile, the matrix microstructure evolved and consequently, the mechanical properties of the composite were improved. However, all parameters saturated at higher ARB cycles suggesting the limitation of further cycles in strengthening composites. These findings are significant for enhancing the knowledge about the microstructure and mechanical properties of particle reinforced composite and optimizing the fabrication of composites by ARB.

(a) is a variation of Al2O3/Al composite tensile strength and elongation with increasing ARB cycles, and SEM pictures showing the fractography of Al2O3/Al composites processed by (b) 8, (c) 14, and (d) 18 ARB cycles.