Metallurgical Abstracts on Light Metals and Alloys vol.55

Effect of Copper Coating on Interfacial Properties, Interfacial Thermal Resistance, Microstructure Evolution and Mechanical Properties of Aluminum Matrix Composites

Ying Guo*, Wen-quan Li*, Xin-gang Liu**, Kenjiro Sugio*, Yu-jiao Ke**, Kai-yao Wang**, Wen-chuang Liu* and Gen Sasaki*

*Graduate School of Advanced Science and Engineering, Hiroshima University

**College of Mechanical Engineering, Yanshan University

[Published in Journal of Alloys and Compounds Vol.917 (2022), 165376]

https://doi.org/10.1016/j.jallcom.2022.165376

E-mail: gen[at]hiroshima-u.ac.jp

Key Words: Al matrix composites, copper coating, interface, mechanical properties, thermal properties

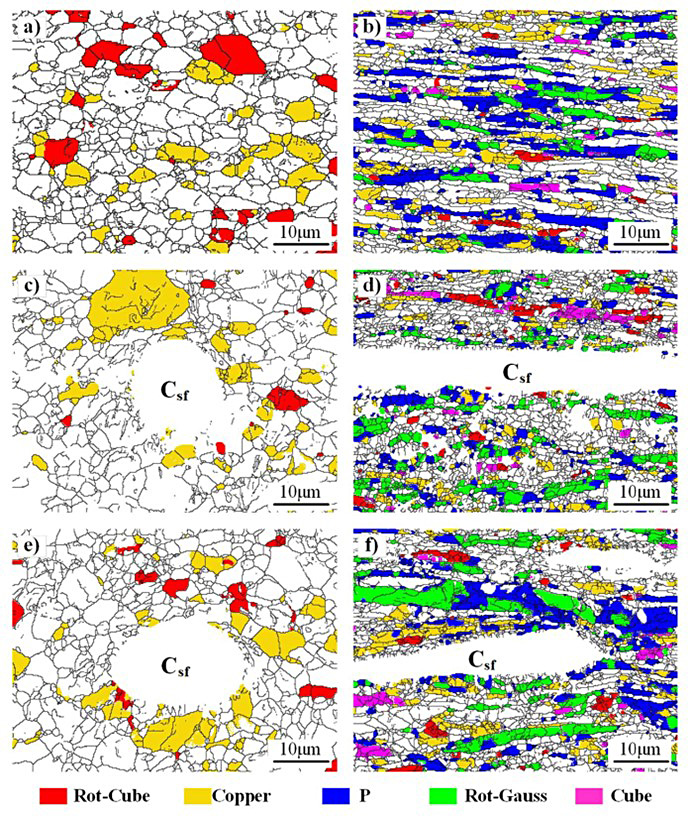

In this study, uncoated and copper-coated short carbon fiber reinforced aluminum matrix composites were prepared by spark plasma sintering. The arrangement of the short carbon fibers was changed by hot rolling. The effect of copper-coating on microstructure evolution and properties was investigated. The results show that the copper-coating can inhibit the formation of harmful product Al4C3 at the interface and protect the structure of short carbon fibers from being damaged during hot rolling. Thus, the hot-rolled copper-coated composites have higher yield strength and better thermal conductivity. The interfacial product and its thickness affect the interfacial thermal resistance. For the interfacial product with low thermal conductivity, the thickness of the product is proportional to the interfacial thermal resistance. The dynamic recrystallization mechanisms of uncoated and copper-coated composites include the continuous dynamic recrystallization mechanism, grain nucleation mechanism of the shear band, and the rotated-Gauss component promoting nucleation mechanism. The copper-coating enhances the interfacial coherence and promotes the nucleation and growth of P-oriented grains and rotated-Gauss-oriented grains by promoting the movement of shear bands.

Distribution of different textures: a) Sintered pure Al, b) Hot-rolled pure Al, c) Sintered Csf/Al, d) Hot-rolled Csf/Al, e) Sintered Cu-Csf/Al, f) Hot-rolled Cu-Csf/Al.