Metallurgical Abstracts on Light Metals and Alloys vol.55

Orientation control of carbon fibers and enhanced thermal/mechanical properties of hot-extruded carbon fibers/aluminum composites

Li-Fu Yi, Takashi Yamamoto, Tetsuhiko Onda and Zhong-Chun Chen

Department of Mechanical and Aerospace Engineering, Graduate School of Engineering, Tottori University

[Published in Diamond and Related Materials, Vol. 116 (2021), pp. 108432]

https://doi.org/10.1016/j.diamond.2021.108432

E-mail: chen[at]mech.tottori-u.ac.jp

Key Words: Electroless nickel coating, Hot extrusion, Carbon fibers/Al composite, Thermal conductivity, Coefficient of thermal expansion

Abstract: Electroless nickel (Ni)-coated carbon fibers (CFs)/aluminum (Al) composites were prepared by a hot-extrusion process. The effects of Ni-coating and extrusion temperature on microstructure, thermal conductivity (TC), coefficient of thermal expansion (CTE), and compressive strength of CFs/Al composites have been systematically investigated. Microstructural observations showed that the CFs in hot-extruded composites were preferentially oriented along the extrusion direction. The Ni coating on CFs resulted in higher relative density of CFs/Al composites, more homogeneous distributions of CFs in the Al matrix, and stronger interfacial bonding between CFs and Al. As a result, the extruded Ni-coated CFs/Al samples showed higher TC, lower CTE, and higher compressive strength in comparison with uncoated CFs/Al extruded samples and Ni-coated CFs/Al spark plasma sintered (SPSed) samples. For example, the Ni-coated CFs/Al sample extruded at 500 °C showed TC, CTE, and compressive strength values of 227 W m-1 K-1, 7.32 ppm K-1, and 113 MPa, respectively, which correspond to 18%, -22%, and 38% enhancements compared to the SPSed sample.

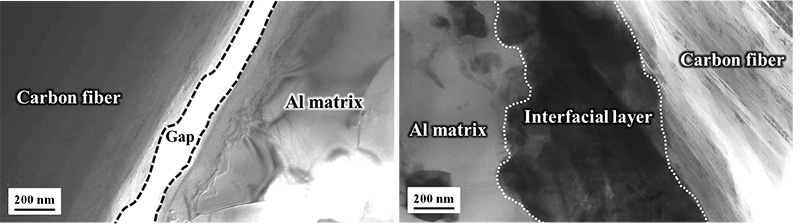

A gap can be observed between CF and Al matrix in the uncoated CFs/Al sample, while an interfacial layer can be seen between CF and Al matrix in the Ni-coated CFs/Al sample.