Metallurgical Abstracts on Light Metals and Alloys vol.55

Corrosion behavior in 5 wt. % NaCl aqueous solution of the Mg(OH)2/Mg-Al LDHs/AlO(OH) composite film prepared by the steam coating on Mg alloy AZCa612

Kae Nakamura1, Yuma Nagashima2, Hiraku Muto2, Ryo Nakano2 and Takahiro Ishizaki3

1Department of Precision Machinery Engineering, College of Science and Technology, Nihon University

2Materials Science and Engineering, Graduate School of Engineering and Science, Shibaura Institute of Technology

3Department of Materials Science and Engineering, College of Engineering, Shibaura Institute of Technology

[Published in Journal of the Electrochemical Society, Vol. 169 (2022) 021508]

https://doi.org/10.1149/1945-7111/ac54db

E-mail: ishizaki[at]shibaura-it.ac.jp

Key Words: Steam coating, Corrosion resistant film, Magnesium alloy

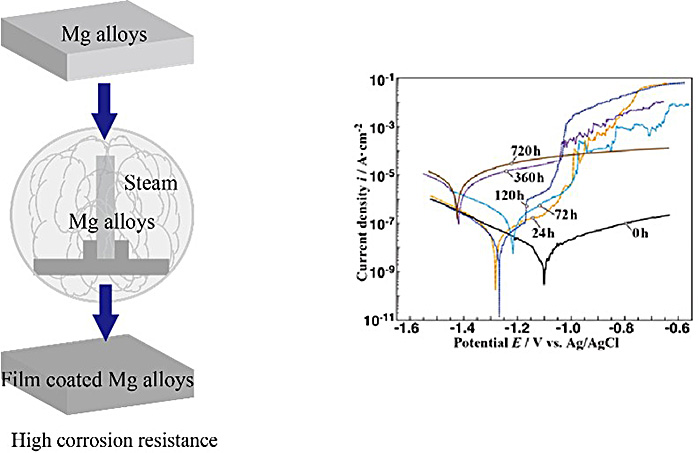

This study investigated the corrosion behavior of the corrosion-resistant films steam coated on AZCa612 magnesium alloy. The film samples were corroded by immersing them in 5 wt. % NaCl aqueous solution for a predetermined time. The corroded films were characterized using scanning electron microscopy, energy-dispersive X-ray spectroscopy, glancing angle X-ray diffraction, Fourier transform infrared spectroscopy, potentiodynamic polarization measurements, hydrogen generation measurements, and electrochemical impedance spectroscopy. The amount of Mg-Al-CO3 layered double hydroxides (LDHs) in the film slightly decreased from the beginning of immersion to 120 h after immersion and gradually increased thereafter. Mg-Al-Cl LDHs were formed after 6 h of immersion and rapidly grew as the immersion progressed. In addition, even with the gradual decrease in the corrosion resistance of the film, there was no major damage observed on the substrates. These results indicate that the corrosion protection mechanism varied with the immersion time. The corrosion-resistant property under a short immersion time could be attributed to the high corrosion resistance of Mg(OH)2 and AlO(OH), whereas it is attributed to the coverage provided by the Mg-Al-Cl and Mg-Al-CO3 LDHs under a longer immersion duration.

Anticorrosive magnesium hydroxide composite films were prepared on magnesium alloy by steam coating. The corrosion resistance was lowered with an increase in the immersion time.