Metallurgical Abstracts on Light Metals and Alloys vol.55

Phase transformations in Al-Ti-Mg powders consolidated by high-pressure torsion: Experiments and first-principles calculations

Yongpeng Tanga,b, Mitsuhiro Murayamac,d, Kaveh Edalatia, Qing Wangae, Satoshi Iikuboe, Takahiro Masudaf, Yuji Higog, Yoshinori Tangeg, Yasuo Ohishig,

Masaki Mitob and Zenji Horitaa,b,h,i

aWPI, International Institute for Carbon-Neutral Energy Research (WPI-I2CNER), Kyushu University, Fukuoka 819-0395, Japan

bGraduate School of Engineering, Kyushu Institute of Technology, Kitakyushu 804-8550, Japan

cDepartment of Materials Science and Engineering, Virginia Polytechnic Institute and State University, Blacksburg, VA 24061, USA

dInstitute for Materials Chemistry and Engineering, Kyushu University, Kasuga 816-8580, Japan

eDepartment of Life and Systems Engineering, Kyushu Institute of Technology, Kitakyushu 808-0196, Japan

fDepartment of Mechanical Engineering and Materials Science, Yokohama National University, Yokohama 240-8501, Japan

gJapan Synchrotron Radiation Research Institute, Hyogo 679-5798, Japan

hMagnesium Research Center, Kumamoto University, Kumamoto 860-8555 Japan

iSynchrotron Light Application Center, Saga University, Saga 840-8502, Japan

[Published in Journal of Alloys and Compounds Vol. 889 (2021), 161815]

https://doi.org/10.1016/j.jallcom.2021.161815

E-mail: mitoh[at]mns.kyutech.ac.jp

Key Words: Al-Ti-Mg alloys, high-pressure torsion, first-principles calculations

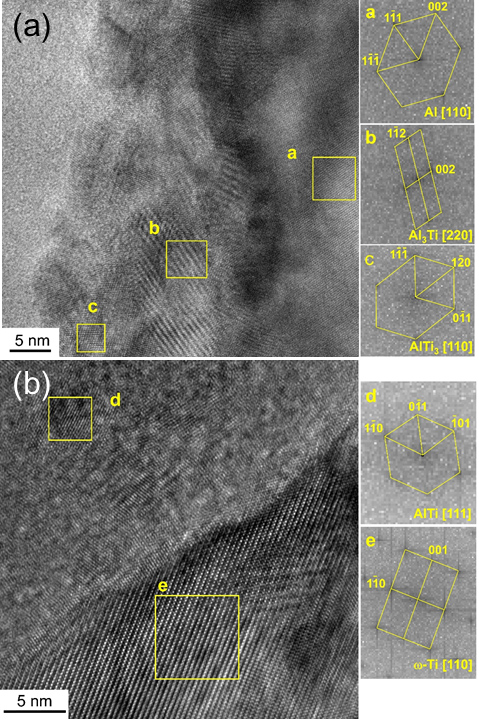

A powder mixture of Al-Ti-Mg with an equal atomic fraction was subjected to severe plastic deformation using high-pressure torsion (HPT) under 6 GPa at room temperature for full consolidation. Microstructural evolution with respect to straining and annealing was examined by X-ray diffraction (XRD) analysis and high-resolution transmission electron microscopy. The XRD analysis revealed that Ti prevails in the consolidated sample and a phase transformation occurs from α phase to ω phase during HPT processing while the total fraction of the ω phase increases with straining. Grain refinement to ~100 nm was achieved through the HPT processing for 100 revolutions as well as the formation of nanograined intermetallics such as Al3Ti, AlTi3 and TiAl. The hardness gradually increases with straining, and further increases by annealing at 573 K for 1.5 h due to the formation of an Al12Mg17 phase despite the fact that the harder ω phase was reversely-transformed to the softer α phase and grains were coarsened to ~450 nm. First-principles calculations show that Al and Mg elements are dissolved into the ω-Ti during HPT processing.

TEM high-resolution lattice images and diffractograms of (a) Al, Al3Ti, and AlTi3, and (b) AlTi and ω-Ti in sample processed by HPT for 100 revolutions.