Metallurgical Abstracts on Light Metals and Alloys vol.55

Pore Formation and Shape Control Simulation of Lotus Aluminum by Phase Field Method

Kei Takahashi*, Yasushi Sasajima* and Teruyuki Ikeda*

*Department of Materials Science and Engineering, Graduate School of Science and Engineering, Ibaraki University

[Published in ACS Omega 2022 7 (17), 14985–14993]

https://doi.org/10.1021/acsomega.2c00733

E-mail: yasushi.sasajima.mat[at]vc.ibaraki.ac.jp

Key Words: Lotus metal, Pore growth process, Directional solidification, Multi-phase field method, PD control

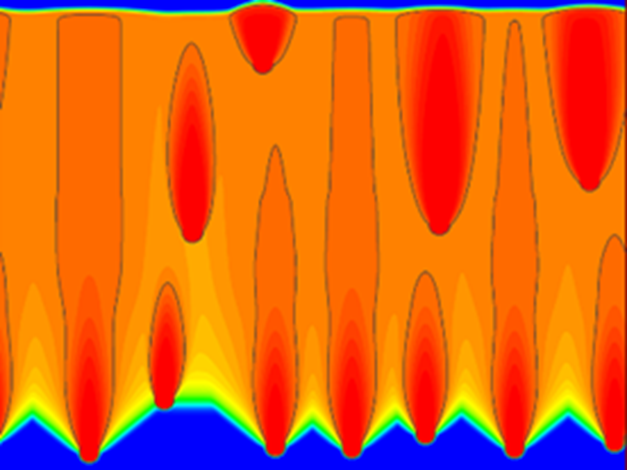

We have simulated pore formation and shape control of lotus aluminum by the phase field method. The simulated material, lotus aluminum, contains anisotropic internal pores, and it is produced by the continuous casting method in a hydrogen atmosphere. The simulation varied the movement speed of the temperature gradient zone by proportional-differential (PD) control with the pore width as the target value. As a result, simple PD control ensured the pores closed during the growth process. To mitigate necking of the pore, PD control was done only when the pore width became larger than the target value under the conditions such that the pore expanded easily (i.e., the pull-out movement was stopped for a certain time immediately after nucleation and the initial speed of the temperature gradient zone was decreased). Then we found the best condition to get linear pore growth without necking. Under the same condition, we simulated multiple pore growths by allowing multiple nucleations. As a result, we observed that although the shape control was applied only to a certain single pore, the other pores also grew linearly if the timing of their nucleation was close to that of the target pore.

Phase field of the pore obtained in a system with multiple nucleation.