In purification processes of aluminum melt, mechanical stirring has been utilized for degassing and/or removing unnecessary chemicals. The molten salt flux and/or reactive gas are injected from the impeller bottom. The fragmentation of molten salt or gas is important to enhance the purification reaction. However, the fragmentation mechanism is difficult to understand because the melt is opaque and the turbulent flow affects the fragmentation. To reveal the phenomena, we carried out the water model experiment and numerical simulation.

A 4-bladed impeller was rotated in a cylindrical water vessel and a single bubble was injected below the impeller. The dynamic movement of bubble was recorded by a high-speed camera. The frame rate was set to 500 fps. In the same condition, numerical simulation was carried out. To represent the motion of liquid-gas interface, an algebraic volume of fluid method was used. The impeller rotation was represented by sliding mesh motion and cyclic arbitrary mesh interface boundary condition. The turbulent flow was modeled by large eddy simulation.

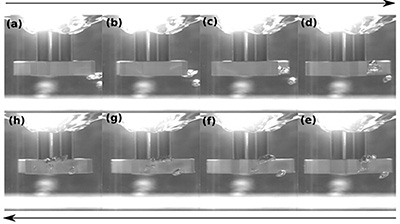

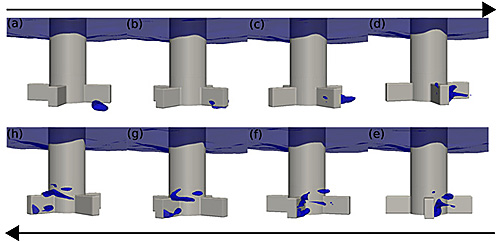

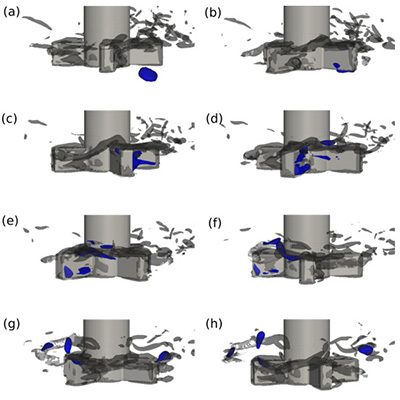

Figure 1 shows the time variation of the bubble shape when the impeller rotating rate is 300 rpm. First bubble moves behind the impeller blade and the bubble is fragmented there. Figure 2 shows the simulation result of bubble dynamic movement during mechanical stirring when the impeller rotating rate is 300 rpm. In the same way as the experimental results as shown in Fig. 1, the bubble moves behind the blade and it is fragmented there. To understand the mechanism of fragmentation, we focused on the structures of turbulent vortices. Figure 3 shows the time variation of the structure of turbulent vortices and bubble shape at 300 rpm rotation rate. At the behind the impeller blade, strong turbulent vortices develop. When a bubble moves behind the blade, the turbulent vortices cut off the bubble and small fragmented bubbles are generated. Therefore, the key factor to fragment the bubble during mechanical stirring is turbulent vortices.