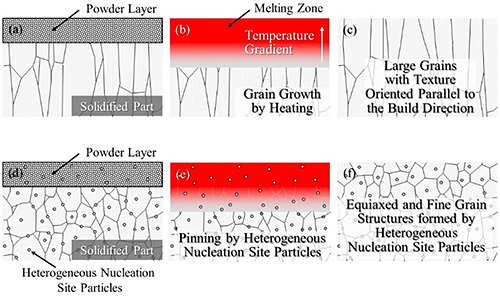

Microstructural evolution during the selective laser melting (SLM) method using conventional Ti-6Al-4V powder is illustrated in Figs. 1(a)-(c). A consequence of repeated melting and deposition under a thermal gradient is the epitaxial growth of Ti-6Al-4V to form coarse primary columnar β-Ti grains. In addition, solid-state β-grain growth is caused by the high temperature thermal cycles associated with layer-by-layer manufacturing, as shown in Fig. 1 (b). As a result, the microstructure of the additive manufactured (AMed) sample has large and elongated grains with texture oriented parallel to the building direction, as shown in Fig. 1 (c). However, this epitaxial growth does not necessarily correlate to enhanced mechanical performance in all situations. Moreover, unwanted porosity caused by incorrect processing parameters or manufacturing conditions, surface roughness and other surface defects are other problems to be overcome. Meanwhile, the equiaxed grain structure of Al alloy castings ensures uniform mechanical properties, reduced ingot cracking, improved feeding to eliminate shrinkage porosity, the distribution of secondary phases and microporosity on a fine scale, and improved machinability and cosmetic features. One of the methods to obtain the equiaxed grain structure of Al alloy castings involves the addition of grain refiners, such as Al-Ti alloy, Al-Ti-B alloy, and Al-Ti-C alloy systems containing heterogeneous nucleation site particles. Therefore, the shortcomings of AM may be overcome by the addition of heterogeneous nucleation site particles in the metallic powder because equiaxed and fine grain structures are promoted during heterogeneous solidification with heterogeneous nucleation site particles. On the basis of this background, authors have proposed to adopt the heterogeneous nucleation theory to improve the microstructure and mechanical properties of AMed Ti-6Al-4V samples, as shown in Figs. 1(d)-(f). In addition, grain growth may be prohibited by the pinning effect in the presence of the heterogeneous nucleation site particles, as shown in Fig. 1(e). Equiaxed and fine grain structures are also promoted by heterogeneous solidification with heterogeneous nucleation site particles, as shown in Fig. 1(f). A homogeneous microstructure is expected to form simultaneously by the addition of heterogeneous nucleation site particles, which results in better formability of the AMed samples.

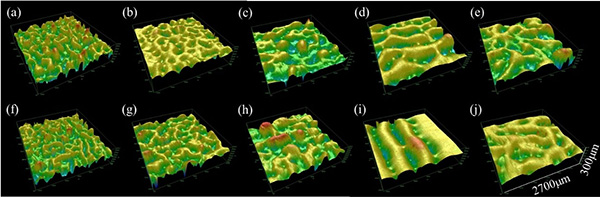

Noncontact 3D evaluation of surface features with submicron resolution can be easily performed with laser confocal microscopy. The evaluation area in this study was selected to be 3.0 mm × 3.0 mm, and height-based coloring was conducted. Figure 2 shows the 3D surface morphologies of the 3D printed samples obtained by laser microscopy. Rough concave-convex structures appeared with an increase in the energy density, and the height of convex structures becomes larger, which may be due to the balling effect phenomenon. Ellipsoidal balls with diameters of 500 µm are reported to occur due to reduced wettability. It should be noted that the height of the convex structures formed in the samples manufactured with TiC particles, especially those manufactured at high energy density, were smaller than those formed in the samples manufactured without TiC particles.

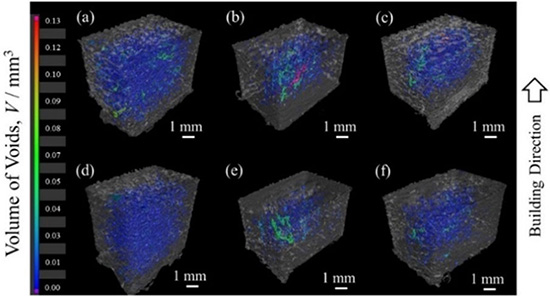

3D images of the AMed samples made semi-transparent to view the location, shape and sizes of the defects are shown in Fig. 3. The images shown in Figs. 3(a) to (c) were obtained from samples without the TiC particles, while those in Figs. 3(d) to (f) are from samples with the TiC particles. The samples shown in Figs. 3(a, d) were manufactured with an energy density of 269 J/mm3, those in Figs. 3(b, e) were manufactured at 405 J/mm3, and those in Figs. 3(c, f) were manufactured at 540 J/mm3. The largest pores are colored with red in these figures, while the smallest pores are colored with blue. Many pores were observed in the sample manufactured without the TiC particles, and the larger pores are visible, as shown in Figs. 3(a-c). It is clear that the samples manufactured with TiC heterogeneous nucleation site particles have much less porosity than the samples produced without TiC particles, as shown in Figs. 3(d-f).

The relative densities of the AMed samples were obtained from X-ray computed tomography (X-CT) data. The relation between the energy density and relative density of the samples manufactured with and without TiC heterogeneous nucleation site particles is shown in Fig. 4. Higher density is obtained as the energy input is increased, and vice versa. At low energy densities, the size of the melt pool generated by the laser is small, which leads to a layered microstructure with a melted layer and a sintered layer, whereas an increase of the energy density results in the development of a melt pool and thus lower porosity. It should be noted that since uniform microstructure and the suppression of pore formation could be achieved by heterogeneous solidification, the density of Ti-6Al-4V samples could be increased by the addition of TiC particles. Therefore, enhanced mechanical properties for AMed products can be achieved by the addition of heterogeneous nucleation site particles into the metallic powder.