Recentl, several researchers have reported higher strength in Al-Zn-Mg alloys by high-pressure torsion (HPT), one of the typical methods of severe plastic deformation, than by age-hardening treatment. In this study, we have investigated the effect of cold rolling on the strength and resistance to hydrogen embrittlement in an Al-8%Zn-2%Mg-2%Cu-0.15%Zr alloy by means of tensile test in the environments of dry nitrogen gas and humid air with 90 % relative humidity at several initial strain rates.

The sheet specimens of 10 mm thick were solution-treated at 480 °C for 1 h, water-quenched and subsequently rolled to 1 mm in thickness at room temperature, where intermediate annealing was made to obtain 1 mm thick samples with cold-rolling reduction of 40 % and 65 %. A part of the sheet cold-rolled by 65 % was solution-treated again, and heat treated at 120 °C for 24 h (T6). Tensile test pieces were made from these sheet specimens and the tensile tests were made at initial strain rates of 1.67![]() 10-4, 1.67

10-4, 1.67![]() 10-6 and 1.67

10-6 and 1.67![]() 10-7 s-1 in dry nitrogen gas (DNG) and in humid air (HA) where the relative humidity was controlled to be above 90 %.

10-7 s-1 in dry nitrogen gas (DNG) and in humid air (HA) where the relative humidity was controlled to be above 90 %.

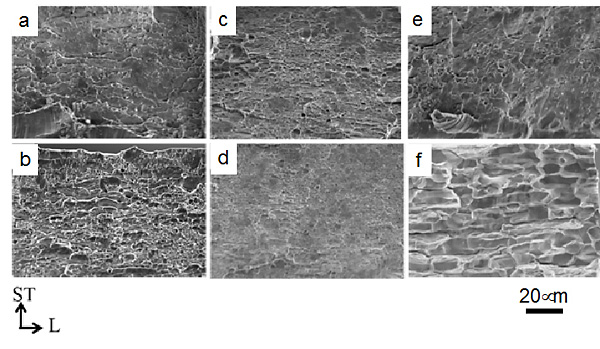

Figure 1 shows effect of cold reduction on the tensile properties in HA and DNG environments at an initial strain rate of 1.67![]() 10-6 s-1. The cold-rolled specimens show higher tensile strength than the specimen heat-treated to peak-aged condition. It is noted that the cold-rolled specimens are not susceptible to hydrogen embrittlement. Figure 2 shows SEM images of the fracture surface of the specimens tested at an initial strain rate of 1.67

10-6 s-1. The cold-rolled specimens show higher tensile strength than the specimen heat-treated to peak-aged condition. It is noted that the cold-rolled specimens are not susceptible to hydrogen embrittlement. Figure 2 shows SEM images of the fracture surface of the specimens tested at an initial strain rate of 1.67![]() 10-6 s-1. The peak aged specimen shows brittle intergranular fracture (Fig. 2 (f)) after the test in HA, while the other specimens show ductile behavior with dimples on the fracture surface. Figure 3 shows effect of initial strain rate on tensile properties. The cold-rolled specimens show higher elongation in the tests at lower strain rate irrespective of testing environment. This result also supports that the cold-rolled specimens are not susceptible to hydrogen embrittlement.

10-6 s-1. The peak aged specimen shows brittle intergranular fracture (Fig. 2 (f)) after the test in HA, while the other specimens show ductile behavior with dimples on the fracture surface. Figure 3 shows effect of initial strain rate on tensile properties. The cold-rolled specimens show higher elongation in the tests at lower strain rate irrespective of testing environment. This result also supports that the cold-rolled specimens are not susceptible to hydrogen embrittlement.