Key words; β-phase Ti alloy, Single crystal, Selected laser melting, Biomaterials, Stress shielding, Low Young's modulus

Ti based alloys were important candidate for metallic bio-materials due to good mechanical properties and superior biocompatibility [1]. The custom-made metallic implants, for example artificial joint, have different shape one by one. It is difficult to deal with manufacturing of custom-made implants by the traditional mass production. Thus, a selective laser melting (SLM) in powder-bed additive manufacturing (AM) process has attracted attention to quickly fabricate custom-made implant with complex shape [2]. This process steps are as follows: (i) Preparing the pre-alloyed powders and three-dimensional (3D) computer-aided design data, (ii) One layer of metal powder is selectively melted and solidified by laser beam, (iii) The starting plate is lowered by one layer thickness, (iv) The rake feeds a new metal powder layer, (v) Above process is repeated to produce a 3D structure.

The difficulty in this fabrication process of titanium alloys due to their technical difficulties and the cost of pre-alloyed powder, resulting in a limited usage of titanium alloys. To overcome this problem, it is effective to fabricate the Ti alloys by SLM from mixture of pure elemental powders. However, there are a little research of the manufacturing of the Ti alloys by SLM from the mixture of pure elemental powders [3]. Therefore, the purpose of the present study is trying to the fabrication of the Ti alloys from the mixture of pure elemental powders via SLM.

Ti-20at.%X (X = Cr, Nb) alloy specimens were prepared by selected laser melting from the mixture of pure elemental powders. Cubic samples of 10 mm ![]() 10 mm

10 mm ![]() 10 mm (building direction, Z-axis) size were manufactured by utilizing a SLM apparatus (EOS M 290, EOS, Germany) equipped with a ytterbium fiber laser in an argon atmosphere. Figure 1 shows an obtained cubic sample of Ti-20at.%Cr alloy. The laser was basically scanned zig-zag pattern in one direction (X-scan) and subsequently rotating the laser by 90° to the second direction (Y-scan). The X- and Y-scans were performed on each layer. The specimens were cut by electro-discharge machining from the center of the as-build cubic specimens. In addition, the same composition alloys (Ti-20at.%Cr and Ti-20at.%Nb) were also made by an arc melting method. The specimens for some measurements were cut by electro-discharge machining from an obtained as-cast ingots by arc melting.

10 mm (building direction, Z-axis) size were manufactured by utilizing a SLM apparatus (EOS M 290, EOS, Germany) equipped with a ytterbium fiber laser in an argon atmosphere. Figure 1 shows an obtained cubic sample of Ti-20at.%Cr alloy. The laser was basically scanned zig-zag pattern in one direction (X-scan) and subsequently rotating the laser by 90° to the second direction (Y-scan). The X- and Y-scans were performed on each layer. The specimens were cut by electro-discharge machining from the center of the as-build cubic specimens. In addition, the same composition alloys (Ti-20at.%Cr and Ti-20at.%Nb) were also made by an arc melting method. The specimens for some measurements were cut by electro-discharge machining from an obtained as-cast ingots by arc melting.

The absolute densities of the products were measured by the Archimedes method and the relative densities of the products were calculated using the theoretical density of the mixture of pure Ti and X (X = Cr, Nb). X-ray diffraction (XRD; Rigaku Rint2000) analysis using Cu-Kα radiation was carried out to identify the constituent phases. The microstructures were observed using an optical microscope. Specimens were etched using a solution consisting of 2.5 mL of HF, 4.5 mL of HNO3 and 250 mL of H2O for the optical microscope observations.

XRD patterns were obtained from the cross-section planes of the as-build cubic specimen and as-cast ingots by an arc melting. Firstly, all the examined as-build specimens were not exhibit the peak of pure Ti, Cr and Nb. Thus, it was succeeded the manufacturing of the Ti alloys by SLM from the mixture of pure elemental powders. The Ti-20at.%Cr alloys exhibit almost the same sharp peaks corresponding to the bcc phase, regardless of the manufactured processes. However, as-build Ti-20at.%Nb alloy exhibits the different phase constitution from as-cast Ti-20at.%Nb alloy as shown in Fig. 2. In particular, the volume fraction of the α” martensite phase is reduced in as-build Ti-20at.%Nb alloy than that of as-cast Ti-20at.%Nb alloy.

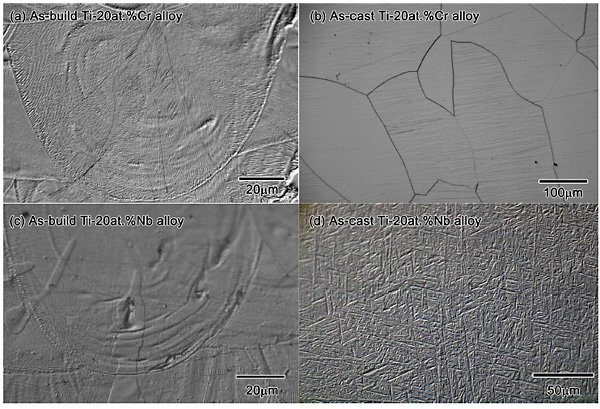

Figure 3 shows the micrographs of all the examined alloys. As-build Ti-20at.%Cr alloy and as-build Ti-20at.%Nb alloy show trace of the melt pools. Cell structure was also observed from the edge of the molten pool in these alloys. This implies that the cooling rate is very fast and cell structure elongated along <001> direction. Moreover, this means that it can be control the grain size and crystallographic orientation of β phase by melt pool shape which can be managed to the energy density and scan strategy during SLM process [4]. It is very important to control the crystallographic texture which leads reduction of Young’s modulus [5]. As-build Ti-20at.%Nb alloy does not exhibit surface relief of α” martensite although as-cast Ti-20at.%Nb alloy clearly shows that. This result is corresponding to the XRD measurements. This differences of microstructure possibly are caused by the cooling rate and the local heat treatment under melting pool [6]. These results implies that it can be also controlled the phase constitution of Ti alloys by energy density and scan strategy. The investigation of the controlling of the texture of β phase and the phase constitution of the non-equilibrium phase by SLM process is currently in progress.