Carbon nanotubes (CNTs) have attracted great attention for reinforcements for composites materials [1] because of ultrahigh strength and Young's modulus, and high aspect ratios. The previous studies reported that homogeneous CNT dispersion were achieved in aluminum (Al) metal matrix composites. Recently, nano sized carbides from the reaction between CNTs and metal matrices are reported as a potential solution to overcoming the weak bonding in CNTs-metal nanocomposite systems. However, it is difficult to the destruction of graphene walls in CNTs and the enhancement of interface to enhance the load transfer efficiency. Therefore, devolving new strong interfacial structures while maintaining the structure of CNTs is required in the area of CNT-reinforced in metal matrix composites. In this study, a new type of strong Al-CNTs interface structure modified with in-situ formed Al2O3 nanoparticles were evaluated by high resolution transmission electronic microscopy (TEM) and in-situ tensile tests.

Pure Al powder (![]() 150 mm in diameter) and CNTs (MWCNTs,

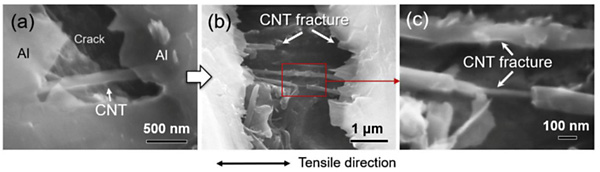

150 mm in diameter) and CNTs (MWCNTs, ![]() 100 nm in diameter) were employed as raw materials. The pre-mixed Al-CNTs powders were consolidated by sparking plasma sintering in vacuum, and then extruded to the full-dense rods. The fracture morphology of Al-CNTs composites after in-situ tensile testing were examined by the field emission scanning electron microscopy and Al-CNTs interface in as-extruded materials were examined by TEM. Figure 1 shows fracture surface CNTs act as bridges to restrain the exposed CNTs fracture into two parts while tensile strain is increased. At the initial stage of plastic deformation of the Al-CNTs composite sample, CNTs are partially exposed in the wake of the micro-cracks and CNTs act as bridges to restrain the growth of cracks (Fig. 1a). By increasing the tensile strain, the exposed CNTs fracture into two parts (Fig. 1b). From the higher-magnification image (Fig. 1c), it is also observed that the outer walls of the two CNTs have been ruptured while the inner part is undamaged. The breaking of CNT walls has been clarified as a result of effective load transfer from Al matrix to CNTs [2]. However, the nature of the Al-CNTs interface leading to the effective load transfer is still unclear.

100 nm in diameter) were employed as raw materials. The pre-mixed Al-CNTs powders were consolidated by sparking plasma sintering in vacuum, and then extruded to the full-dense rods. The fracture morphology of Al-CNTs composites after in-situ tensile testing were examined by the field emission scanning electron microscopy and Al-CNTs interface in as-extruded materials were examined by TEM. Figure 1 shows fracture surface CNTs act as bridges to restrain the exposed CNTs fracture into two parts while tensile strain is increased. At the initial stage of plastic deformation of the Al-CNTs composite sample, CNTs are partially exposed in the wake of the micro-cracks and CNTs act as bridges to restrain the growth of cracks (Fig. 1a). By increasing the tensile strain, the exposed CNTs fracture into two parts (Fig. 1b). From the higher-magnification image (Fig. 1c), it is also observed that the outer walls of the two CNTs have been ruptured while the inner part is undamaged. The breaking of CNT walls has been clarified as a result of effective load transfer from Al matrix to CNTs [2]. However, the nature of the Al-CNTs interface leading to the effective load transfer is still unclear.

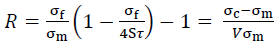

According to the previous study [2], if the interfacial strength (τ) is larger than a critical interfacial stress (τc), CNTs will be fractured. It can be expressed as:

(1)

where σf is the fracture strength (~ 4 GPa [17]) and S is the aspect ratio of CNTs. σc can be calculated as 20 MPa. In the case of CNT fracture, the composite strength (σc) can be expressed as [2]:

(2)

where R is the strengthening efficiency, σc and σm are the strength of composite and matrix, and V is CNT volume content. From Eq. 2,

(3)

Thence, the interface strength is estimated to be 41 MPa. It suggests a strong interface bonding and in agreement with the condition for CNT fracture, i.e., t > tc.

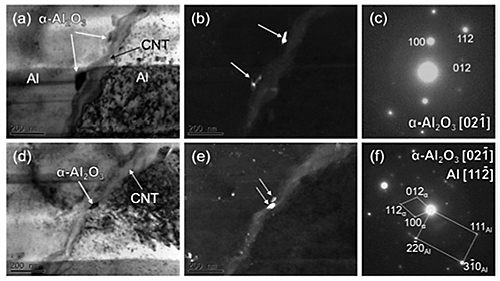

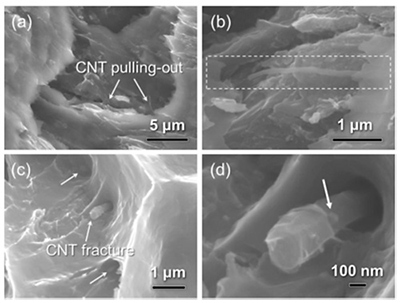

It is well-known that unreacted CNTs have weak bonding to Al matrix because of the poor wettability, however, it reveals the strong Al-CNTs interface is resulted by the anchoring effect of interfacial Al2O3 nanoparticles by TEM observation. Figure 2 shows two typical a-Al2O3 nanoparticles (50-100 nm) are observed at the CNT-Al interface in the composite. It is identified by a combination of bright-field TEM (Figs. 2a and 2d), dark-field TEM (Figs. 2b and 2e) and selected diffraction patterns (Figs. 2c and 2f). A crystal relation between a-Al2O3 and Al is found to be a-Al2O3[02-1]//Al [11-2] (Fig. 2f). It is also found that CNTs shape in composites becomes tortuous compared with straight morphology of CNTs at starting stage [2]. Interfacial Al2O3 nanoparticles play an important role in enhancing Al-CNTs interface and consequent load transfer effect. CNT pulling-out phenomenon is observed in Fig. 3a. As the crack expands after the CNT bridging, one half part of the CNT is entirely pulled-out from the other part in Fig. 3b, as suggests in Fig. 4a. However, as confirmed in Fig. 1, CNT failure mode in the composite with interfacial Al2O3 nanoparticles results in comparatively shorter failure CNTs on the failure surface in Fig. 3c. Some interfacial Al2O3 nanoparticles were also observed on the fractured CNT surface, shown in Fig. 3d. The nanoparticles are probably interfacial Al2O3 nanoparticles because of the similar size and situation observed in TEM, shown in Fig. 2. With the addition of interfacial nanoparticles, tortuous morphology of CNTs in as-extruded composites produce strong anchoring effect of nanoparticles to resist the sliding of CNTs under tensile loading Fig. 4b. As conclusions of this study, Al2O3-modified interfaces can be effectively transferred from Al matrix to CNTs, which leads to CNT fracture during tensile loading (Figs. 1 and 3c).

References:

[1] S. Stankovich, D.A. Dikin, G.H. Dommett, K.M. Kohlhaas, E.J. Zimney, E.A. Stach, R.D. Piner, S.T. Nguyen, R.S. Ruoff, Nature 442 (2006) 282-286.

[2] B. Chen, S. Li, H. Imai, L. Jia, J. Umeda, M. Takahashi, K. Kondoh, Compos. Sci. Technol. 113 (2015) 1-8.