Currently, in the Japanese synchrotron radiation facilities, SPring-8, three-dimensional non-distractive observation with a spatial resolution of 50-160 nm is available constantly in the imaging beamline by utilizing an X-ray focusing device of Fresnel zone plate. The advantages of X-ray tomography are that three-dimensional morphologies are obtained, and that the observation is non-destructive. In Al-Si cast alloys, it is well known that eutectic Si particle strongly effects on mechanical properties. A lot of study with regard to the morphology and distribution of eutectic Si particles have been conducted to date, because the spheroidizing of Si particles brings, in particular, ductility improvement by heat-treatment. The changes of Si particles morphology during a heat treatment are considered as follows; firstly, Si particles with necking divide into parts by Plateau-Rayleigh instability. This separation is a change which decreases system energy quickly. Next, the fragmented Si-particles grow into spherical shapes by diffusion controlled Ostwald ripening to reduce their surface energy. By contrast, self-modification (self-refinement) of eutectic Si-particles is also possible by killing an impurity element of P, which is contained in Si and forms AlP as the solidification nuclei of Si. This P free solidification process has been reproduced by Phase-field model simulation by Eiken. The morphologies of eutectic Si-particles formed in the different solidification processes, which is in self-modification and Sr-modification, are different. Synchrotron radiation nanotomography has revealed that the morphologies of Si-particles in self-modification and Sr-modification are of a rod-like shape and coral-like shape, respectively, by casting self-modified and Sr-modified samples and investigating practically. Therefore, in this study, to clarify the behavior of morphological changes during heat treatment and the effect of them on mechanical properties, hypoeutectic Al-10%Si alloys were cast using two different solidification processes (Self-modification and Sr-modification) that produce different morphology of eutectic Si-particles (rod-like and coral-like). The changes of mechanical properties were investigated in the prepared samples. The three-dimensional morphology changes of eutectic Si-particles during the heat treatment process were observed in both alloys by utilizing nanotomography with Fresnel zone plate and Zernike phase plate.

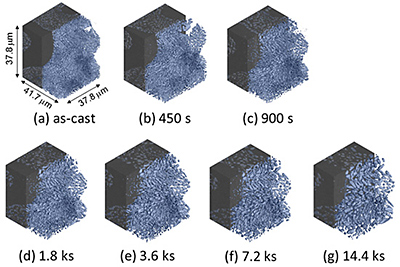

Three-dimensional volume images of eutectic Si-particles in Al-9.8%Si-3ppmP cast alloy, which are obtained by synchrotron radiation nanotomography, are shown in Fig. 1. Interior Si-particles are displayed removing the aluminum matrix in the top part of each figure. It can be confirmed that synchrotron radiation nanotomography is high resolution because the figure indicates the changes in a very small region with a size of 28.4 µm ![]() 56.7 µm

56.7 µm ![]() 27.2 µm. In the as-cast state (heat treatment time, t = 0 s) as shown in Fig. 1(a), most of the eutectic Si-particles are of a straight rod-like shape, and a small plate-like shape is also seen partially. It is observed that the rod and plate-like Si-particles are connecting. Particle growth is confirmed during heat treatment up to 14.4 ks as shown in Figs. 1(b)-(g). The number of particles decrease gradually during particle growth. Although particle separation that makes particles segment into a small size is also observed, most of the particles maintain a high aspect ratio after 14.4 ks annealing.

27.2 µm. In the as-cast state (heat treatment time, t = 0 s) as shown in Fig. 1(a), most of the eutectic Si-particles are of a straight rod-like shape, and a small plate-like shape is also seen partially. It is observed that the rod and plate-like Si-particles are connecting. Particle growth is confirmed during heat treatment up to 14.4 ks as shown in Figs. 1(b)-(g). The number of particles decrease gradually during particle growth. Although particle separation that makes particles segment into a small size is also observed, most of the particles maintain a high aspect ratio after 14.4 ks annealing.

Figure 2 shows a three-dimensional volume image of Al-10.1%Si-4ppmP-108ppmSr cast alloy. In the as-cast state (Fig. 2(a)), fine rod-like Si-particles are observed similar to Al-9.8%Si-3ppmP cast alloy. However, the entire morphology of Si-particles in Sr-modified alloy are that of a coral-like shape with multiple branches. Particle size is slightly finer than that in Al-9.8%Si-3ppmP cast alloy. The Si-particles grow gradually with fragmentation during heat treatment, and spheroidize after 14.4 ks. In Al-10.1%Si-4ppmP-108ppmSr cast alloy, formation of Sr precipitations was confirmed in primary a-Al dendrite during heat treatment. Comparing with three-dimensional volume images in (a) as-cast and (b) after 7.2 ks heat-treated, new Si-particles, which were not found in the as-cast state, were observed in the outside region of eutectic phase in which Si-particles were gathering. The presence of precipitate Si-particles was also confirmed in the slice image. It can be concluded that the particles were not Sr compounds but Si because the particles have disappeared in the absorption images.

The situations, in which particles grow while keeping volume constant, are Ostwald ripening. According to classical particle growth theory, a growth of Ostwald ripening is formulated as

| d3 - d03 = kt, | (1) |

in a diffusion control situation. Here, d and d0 are the average particle diameter and initial average particle diameter, k is constant and t is annealing time. The relationship between the cube of average particle diameter and annealing time in this study is shown in Fig. 3. The early stage of particle growth in Al-9.8%Si-3ppmP cast alloy does not correspond to the growth manner expressed in equation (1). The Si-particles grow proportionally after 3.6 ks of heat treatment. The particle growth in Al-10.1%Si-4ppmP-108ppmSr cast alloy almost obeys the equation (1) though a little difference is seen in the early stage of growth. It is found that Si-particle growth in Al-10.1%Si-4ppmP-108ppmSr cast alloy is faster than that in Al-9.8%Si-3ppmP cast alloy. A very small difference in particle growth rate had been expected because the alloys were simple binary Al-Si system alloys though there was a difference in 108ppm Sr content. However, a six times difference is recognized in the comparison with the slopes of fitting lines between both of the alloys in the later stage of growth.

The morphology of eutectic Si-particles was rod-like in shape in the self-modified sample of Al-9.8%Si-3ppmP cast alloy. In the Sr-modified sample of Al-10.1%Si-4ppmP-108ppmSr cast alloy, Si-particle was a coral-like shape in the as-cast. The coral-like shape particles observed in Al-10.1%Si-4ppmP-108ppmSr cast alloy fragmented at branch and neck during heat treatment at 773K. The fragmentation occurred up to 900 s. After that, the fragmented particles grew and spheroidized by Ostwald ripening. The rate of Ostwald ripening in Al-10.1%Si-4ppmP -108ppmSr cast alloy was faster than that in Al-9.8%Si-3ppmP cast alloy. On the other hand, rod-like shaped eutectic Si-particles observed in Al-9.8%Si-3ppmP cast alloy were larger in size compared to the particle size in Al-10.1%Si-4ppmP-108ppmSr cast alloy. In Al-9.8%Si-3ppmP cast alloy, separation of eutectic Si-particles occurred up to approximately 900 s as well as that in Al-10.1%Si-4ppmP-108ppmSr cast alloy. The frequency of separation was low due to not the coral-like shape but the rod-like shape. Three-dimensional morphology changes of fine eutectic Si-particles in both cast alloys, which is fragmentation and spheroidizing, can be connected to changes in mechanical properties. In the rod-like shape of Si-particles obtained in a self-modified sample of Al-9.8%Si-3ppmP cast alloy, however, it was found that the morphology change behavior was very complex. By non-destructive continuous observation using nanotomography, it was revealed that relatively long rod-shape particles grew slowly without separation. It is also observed that a protuberance was absorbed into a small plate-shape part. Moreover, very complex behavior occurred where a rod-shape particle separated at the neck, spheroidized and was then absorbed by a neighboring larger particle was observed.