When a metal-based composite containing solid particles is subjected to severe plastic deformation (SPD) processing, the particle distribution in the composite changes drastically. This is because the matrix around the particles in the composite is severely deformed during SPD. If the particle distribution is changed by SPD, the mechanical properties of the composite would be affected. Therefore, precious evaluations for the size, the shape and the spatial distribution of the particles in the deformed composites are important.

In previous study, it has been reported that plastic deformation of the metal-based composite containing granular particles can improve the homogeneity of the particles within the composite. However, the distribution behavior of the platelet particles due to SPD for the composite containing the platelet particles would be different from that of the granular particles. This is because that the stress distribution around the particle would depend on the particle shape. In this study, the distributions of the platelet Al3Ti particles in Al-Al3Ti composites deformed by equal channel angular pressing (ECAP) are investigated using both 3-dimensional (3D) microstructural observation and crystallographic analysis. Based on the obtained results, the distribution and fragmentation mechanisms of the platelet Al3Ti particles in the Al-Al3Ti composites deformed by ECAP are discussed.

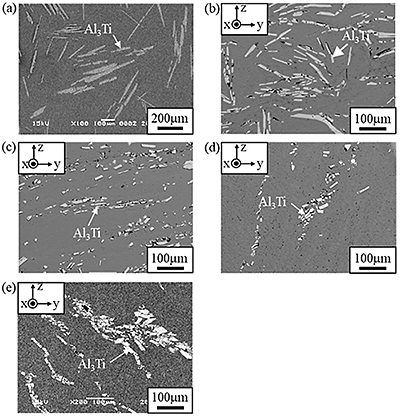

Figure 1 is a set of images obtained by scanning electron microscopy (SEM) showing the microstructure of Al-Al3Ti specimens before and after ECAP. From Fig. 1(a), it is seen that large platelet Al3Ti particles are distributed in the specimen before ECAP. After 1 pass of ECAP is performed, the platelet Al3Ti particles are fragmented, as shown in Fig. 1(b). However, they retain their platelet shape. Figs. 1(c), (d) and (e) show microstructures of the specimens deformed by 4 passes of ECAP under routes A, Bc and C, respectively. The platelet Al3Ti particles in these specimens are severely fragmented, and almost all of the fragments have a granular shape. In the specimen deformed under route A, the fragmented particles are homogeneously distributed in the Al matrix. In contrast, the specimens deformed under routes Bc and C have groups of the fragmented Al3Ti particles. Therefore, the spatial distribution of the fragmented Al3Ti particles in a deformed Al-Al3Ti specimen depends on the processing route.

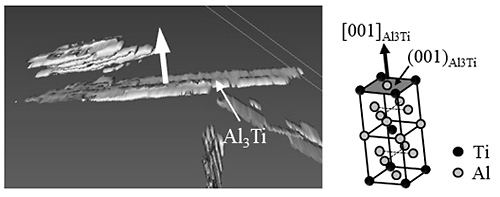

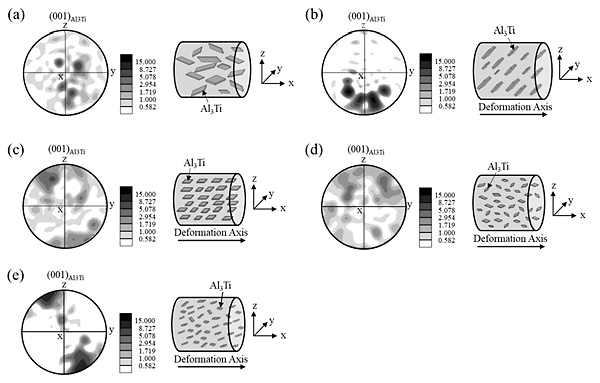

Figure 2 is a set of 3D images of the platelet Al3Ti particles and their crystal lattice structure in the undeformed Al-Al3Ti specimen. This 3D image is obtained by serial sectioning method. From this figure, it is clear that the plane-normal direction of the platelet Al3Ti particle is [001]Al3Ti. Based on these crystallographic characteristics of the Al3Ti particles, the orientation distribution of the fragmented Al3Ti particles in the deformed specimens can be evaluated by texture analysis of (001)Al3Ti. In this study, the (001)Al3Ti texture formed in the Al-Al3Ti specimens was investigated using electron backscattered diffraction (EBSD). Results of the texture analysis are shown in Fig. 3. In each figure, the right and left images are (001)Al3Ti pole figures and schematic illustrations, respectively, showing the orientation distribution of the fragmented Al3Ti particles. From Figs. 3 (a) and (b), it is seen that the fragments in the specimen after 1 pass of ECAP are strongly aligned compared with the undeformed specimen. This is because that the planes of the Al3Ti particle fragments move toward the shearing plane induced by ECAP. Furthermore, as shown in Figs. 3 (c), (d) and (e), the alignments of the fragmented Al3Ti particles in the specimens ECAPed at 4 passes are different depending on processing route. These orientation distributions of the fragments in the ECAPed specimens are related to the material flow of the Al matrix during ECAP.

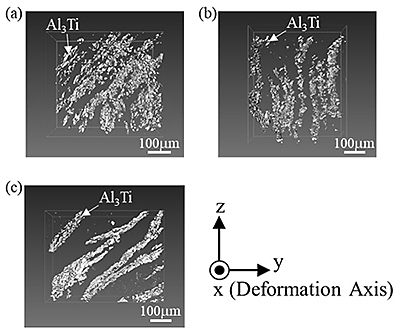

Figures 4 (a), (b) and (c) are 3D images of the Al3Ti particle fragments in the specimens ECAPed under routes A, Bc, and C with 4 passes, respectively. In the specimen ECAPed under route A, the distribution of the granular Al3Ti fragments is relatively random and each particle is relatively isolated. On the other hand, the granular Al3Ti fragments in the specimens deformed under routes Bc and C are gathered together to form several groups. Therefore, it is clear that the spatial distribution of the fragmented Al3Ti particles in the deformed specimens depends on the ECAP processing route. These spatial distributions of the fragments can be explained by the material flow of the Al matrix during ECAP.

In order to consider the fragmentation mechanism of the platelet Al3Ti particles by ECAP, the crystal plane orientation on fracture surfaces of Al3Ti particle fragments is determined based on the results of 3D images and crystallographic analysis. As the results, it is found that the Al3Ti particles are preferentially fragmented on the twin boundary plane of {112}Al3Ti. Therefore, it is concluded that fragmentation of a platelet Al3Ti particle by ECAP occurs along the twin boundary plane after twin deformation.