The preparation of through-hole membranes containing uniform-sized holes on submicron to nanometer scales is important because they can be used in various applications. Anodic porous alumina is a typical material with an ordered through hole arrays. One of characteristic point of anodic porous alumina is good controllability of its geometrical structures based on anodization parameters. The hole intervals and hole sizes are dependent on the applied voltage for anodization. In the present report, we describe a new process for the preparation of anodic porous alumina with site controlled through-holes. This process is based on the formation of the masking layer on the first anodic porous alumina following by the selective second anodization for the readily soluble layer. The advantageous points of this process are controllability of the pattern of the through-holing by changing the mask patterns. In addition, the preparation of the large sized samples with selective through-holing is possible. This is the first report on the formation of large alumina membranes with controlled through-hole sites by a wet process, which is different from the conventional process using a dry etching. The obtained through-hole membranes could be used in various functional devices requiring controlled through-hole sites.

Figure 1 shows a schematic diagram of the preparation of an alumina through-hole membrane with controlled through-hole sites. Al was anodized under a constant voltage of 200 V in 0.1 M phosphoric acid at 0°C for 90 min. To form the resist mask on the surface of the ordered anodic porous alumina, a polydimethylsiloxane (PDMS) stamp, which was formed using a master mold fabricated by electron beam lithography, was used. A thin polychloroprene layer was formed on the surface of the PDMS stamp by dip coating using a toluene solution containing of 0.75 wt% polychloroprene. The PDMS stamp with a thin resist layer was pressed on the porous alumina to transfer the resist pattern to the surface of the alumina layer. Then, the anodic porous alumina with the resist mask was anodized again under a constant voltage of 200 V in undiluted concentrated sulfuric acid (98% purity) at 0°C. This selectively formed a highly soluble alumina layer at the bottoms of holes in the open sites of the resist mask. After the anodization, residual Al substrate was removed using a saturated solution of iodine in methanol, and the highly soluble alumina layer formed in concentrated sulfuric acid was dissolved selectively by a wet-etching using 10 wt% phosphoric acid at 30°C for 5 min.

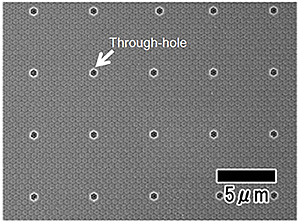

Figure 2 shows typical SEM image of anodic porous alumina with selective through-holing prepared by the present process. From the SEM image, it was confirmed that that selective through-holing was achieved by selective dissolution of the alumina layer formed in concentrated sulfuric acid. The obtained porous alumina membranes will be useful in various applications.