Magnesium has gained attention for use in transport industries as it is the lightest structural metal and has high specific strength. However, deformation mechanisms of magnesium remain unclarified. The main slip system in magnesium is basal slip. As a result, magnesium shows low ductility at room temperature. Therefore, non-basal slip activities are required to improve ductility. It has been reported that the addition of cerium increases room temperature ductility of magnesium and that 0.035 mol% cerium added to magnesium results in alloy strength identical to pure magnesium but with higher ductility due to non-basal slip in compression tests at room temperature. However, effects of cerium addition on non-basal slip systems in magnesium-cerium (MgCe) alloys have yet to be elucidated. This study investigates effects of cerium addition on non-basal slip systems in magnesium by subjecting MgCe alloy single crystals to tensile tests with loading direction parallel to basal planes at room temperature.

Mg-0.016 mol%Ce and Mg-0.052 mol%Ce alloy single crystals were grown by the Bridgman method. The specimen size was approximately 0.3![]() 3

3![]() 20mm3 with the normal planes parallel to basal planes and the longitude direction parallel to [1120] or [1100]. Tensile tests were carried out at room temperature and the initial strain rate was 3.7-4.6

20mm3 with the normal planes parallel to basal planes and the longitude direction parallel to [1120] or [1100]. Tensile tests were carried out at room temperature and the initial strain rate was 3.7-4.6![]() 10-5 /s. Slip lines and twins were observed with a Nomarsky type optical microscope.

10-5 /s. Slip lines and twins were observed with a Nomarsky type optical microscope.

Figure 1 shows stress-strain curves obtained from [1100] tensile tests of Mg-0.016 mol%Ce alloy single crystals. In pure magnesium single crystals, slip deformation occurred in [1120] tensile tests but not in [1100] tensile tests. In contrast, Mg-Ce alloy single crystals yielded and showed a slight ductility of 0.06% in [1100] tensile tests. Thus, it is found that cerium addition improves the ductility of magnesium.

Figure 2 shows stress-strain curves obtained from [1120] tensile tests of Mg-0.052 mol%Ce alloy single crystals and pure magnesium single crystals. Mg-0.052 mol%Ce alloy single crystals yielded at lower stress than pure magnesium single crystals. Mg-0.052 mol%Ce alloy single crystals fractured at a strain of approximately 1.19%, meaning that the ductility of magnesium decreases by the addition of cerium.

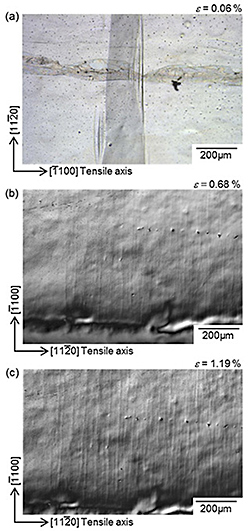

Figure 3(a) shows an optical micrograph of Mg-0.016 mol%Ce alloy single crystals at a strain of 0.06% in [1100] tensile tests. {1011} twin bands were observed. This result indicate that cerium addition facilitates activation of the {1011} twin, resulting in Mg-Ce alloy single crystals displaying slight ductility of 0.06% in the [1100] tensile test. Figures 3(b) and (c) shows optical micrographs of Mg-0.052 mol%Ce alloy single crystals in [1120] tensile tests at a strain of 0.68% and 1.19%, respectively. Fine slip lines of {1122} <1123> second order pyramidal slip (SPCS) were observed. This result indicates that cerium addition no more than 0.052 mol% does not change the slip system. When strain increased up to 1.19%, slip lines became clear and the width of each slip band expanded, as shown in Fig. 3(c).

Figure 4 shows CRSSs for {1011} twin and SPCS as a function of cerium contents. Each CRSS decreased due to cerium addition.

Mg-0.016 mol%Ce and Mg-0.052 mol%Ce alloy single crystals were subjected to tensile tests so as to investigate effects of cerium addition on non-basal slips in pure magnesium. Mg-0.016 mol%Ce alloy single crystals yielded due to {1011} twinning in [1100] tensile tests. On the other hand, Mg-0.052 mol%Ce alloy single crystals yielded due to second order pyramidal slips in [1120] tensile tests similar to pure magnesium. We found that cerium addition decreases critical resolved shear stresses for {1011} twinning and second order pyramidal slips.