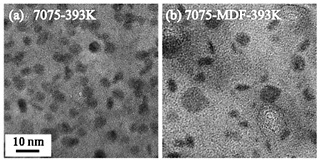

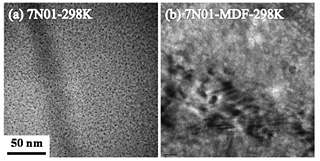

The microstructure and mechanical properties of 7075 and 7N01 alloys after multi-directional forging (MDFing) and subsequent aging were systematically investigated. The number density of the precipitates, η′ phase, in the aged 7075 Al samples after MDFing were lower than that of the aged sample without MDFing (Fig. 1). While the density in the aged sample without MDFing was 1.3![]() 105 µm-2, it in the aged samples after MDFing was 8

105 µm-2, it in the aged samples after MDFing was 8![]() 104 µm-2 and the size distribution was more inhomogeneous. Completely same tendency was observed in the 7N01 Al alloys aged with and without MDFing followed by aging. These differences in the distribution of precipitates should be due to the difference in the density of nucleation sites as dislocations, subboundaries and vacancies.

104 µm-2 and the size distribution was more inhomogeneous. Completely same tendency was observed in the 7N01 Al alloys aged with and without MDFing followed by aging. These differences in the distribution of precipitates should be due to the difference in the density of nucleation sites as dislocations, subboundaries and vacancies.

The samples were tensile tested at room temperature at an initial strain rate of  =3

=3![]() 10-3 s-1. The results are shown in Figs. 3 and 4. The aged 7075 and 7N01 alloys after MDFing showed the ultimate tensile strengths of 556 MPa and 428 MPa, respectively. Even while no specific advantages of MDFing of these alloys before aging was found.

10-3 s-1. The results are shown in Figs. 3 and 4. The aged 7075 and 7N01 alloys after MDFing showed the ultimate tensile strengths of 556 MPa and 428 MPa, respectively. Even while no specific advantages of MDFing of these alloys before aging was found.

The fatigue tests were conducted in air and 3.5% NaCl aqueous solution to investigate the effect of MDF on the fatigue properties of 7000 series alloys. The results of S - N curves of 7N01 alloys are displayed in Fig. 5. As a result of fatigue test in air, the fatigue strength of the MDFed 7N01 alloy was slightly lower than that of non-MDFed one, but that of the 7075 alloy showed no difference before and after MDFing. Two alloys had no significant difference in fatigue crack growth rate in air and 3.5% NaCl aqueous solution.