Since β-AlFeSi intermetallic compound particles formed during solidification of Al-Si-Fe alloys are brittle, large β-AlFeSi particles will decrease the mechanical properties of the as-cast alloys. In this study, fragmentations of β-AlFeSi particles in Al-7 mass%Si-1 mass%Fe alloy are carried out by ECAP (Equal-Channel Angular Pressing), MDF (Multi-Directional Forging), symmetric rolling and asymmetric rolling.

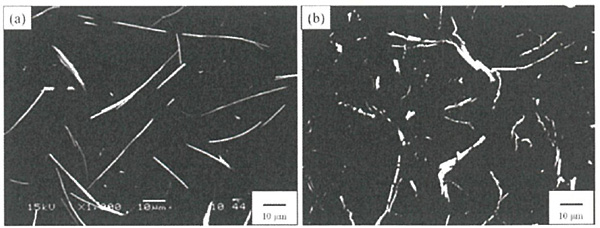

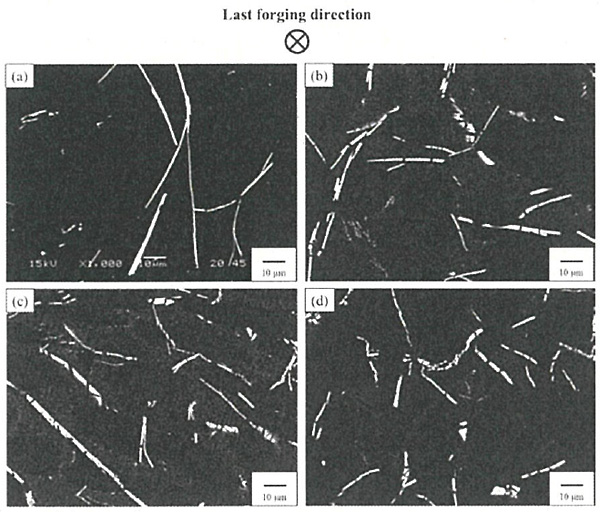

Figures 1 (a) and (b) show SEM photomicrographs showing cast specimen before the ECAP and ECAPed specimen, respectively. The white particles in these figures are β-AlFeSi and black region is the Al matrix. β-AlFeSi particles with plate-type in shape are randomly distributed in Al matrix before the deformation, as seen in Fig. 1 (a). Average lengths of β-AlFeSi particles in the cast specimen before the ECAP and ECAPed specimen are listed in Table 1. It is found that the β-AlFeSi particles in the Al-7 mass%Si-1 mass%Fe alloy can be fragmented by ECAP method. The microstructural evolution of the Al-7 mass%Si-1 mass%Fe alloy during MDFing are shown in Fig. 2. Average lengths of β-AlFeSi particles in the MDFed specimen are also listed in Table 1. As can be seen, the β-AlFeSi particles in the Al-7 mass%Si-1 mass%Fe alloy can be also fragmented by MDF method. The particle size is found to be decreased progressively with increasing MDF passes.

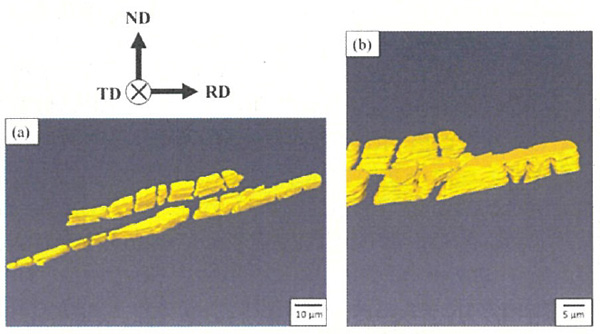

Four different asymmetric rolling tests (normal - one way asymmetric rolling, turn upside down - one way asymmetric rolling, normal - cross asymmetric rolling and turn upside down - cross asymmetric rolling) as well as symmetric rolling were carried. The results are shown in Table 1. It is seen that the average length of β-AlFeSi particles in the asymmetric rolled specimen by turn upside down - one way rolling is smallest. 3-D microstructure of β-AlFeSi in asymmetric rolled specimen by turn upside down - one way rolling is shown in Fig. 3. The β-AlFeSi particles found in the asymmetric rolled specimen by turn upside down - one way rolling have a granular shape. It can be concluded that the asymmetric rolled specimen by turn upside down - one way rolling is an effective process for fragmentation of platelet shaped particles within the metal matrix.