There has been growing interest in the preparation of polymer nanofibers owing to their various applications. Previously, we reported the spinning of polymer nanofibers using ordered anodic porous alumina as a spinneret. Anodic porous alumina is a typical nanohole array material prepared by the anodization of Al in an acidic solution. The hole diameter of the anodic porous alumina can be controlled precisely on the nanometer scale by adjusting the preparation conditions. An ordered anodic porous alumina through-hole membrane, which is formed by the removal of residual Al and the bottom part of the porous alumina, is promising candidate for use a spinneret for the continuous spinning of polymer nanofibers because of its geometrical structure, that is, an array of uniform-size holes. In our previous study,the preparation of polymer nanofibers was carried out by extruding the monomer solution from the holes of the porous alumina membrane under the illumination of UV light. Fine polymer nanofibers with controlled diameters were obtained by the spinning using the porous alumina membrane. However, it is difficult to prepare polymer nanofibers continuously because the photocurable monomer adheres to the surface of the porous alumina spinneret during spinning, causing the holes to become blocked in a short period. To overcome this problem, we introduce the solvent solidification spinning process using a polymer solution prepared by dissolving a polymer in a solvent. Polymer nanofibers were formed continuously by injecting the polymer solution into a congealed solution through the fine holes of a porous alumina spinneret. This is the first report on the preparation of polymer nanofibers with a diameter of less than 100 nm by wet spinning using a spinneret with nanoholes.

In this study, we adopted the anodic porous alumina with selective through-holing as a spinneret. Figure 1 shows a schematic representation of the experimental setup for the continuous spinning of polymer nanofibers using the porous alumina spinneret. The porous alumina membrane with selective through-holes was fixed on top of the nozzle using epoxy resin. The diameter of the opening in the nozzle used in the present study was 2 mm. For the continuous spinning, 10 wt% polyacrylonitrile (PAN) in N,N- dimethylformamide (DMF) was used as the polymer solution, and a mixed solution of water and DMF (1:1 volume ratio) was used as the coagulating solution. The polymer solution was injected into the coagulating solution though the holes in the alumina spinneret using N2 gas at a pressure of 100 kPa. During continuous spinning, the solidified polymer fibers in the coagulating solution were pulled up at a speed of 100 µm/s.

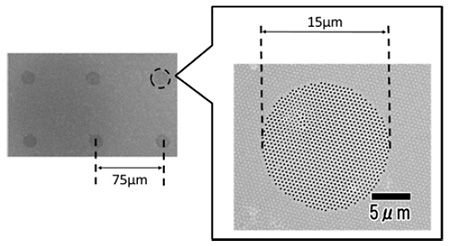

Figure 2 shows the SEM image of the back surface of the anodic porous alumina membrane with selective through-holes used for continuous spinning. From the SEM image shown in Fig. 2, it was observed that the selective through-holing of the anodic porous alumina was carried out by selective removal of the bottom part of the alumina layer.

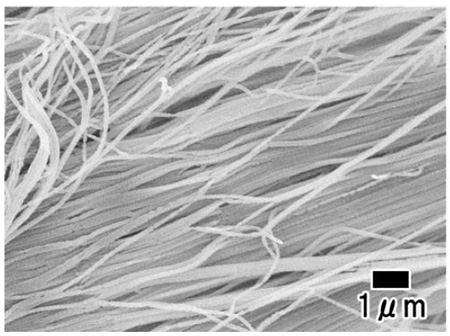

Figure 3 shows the SEM image of PAN nanofibers obtained by continuous spinning using the porous alumina membrane as a spinneret. The SEM image shown in Fig. 3 reveals that PAN nanofibers with a uniform diameter were obtained. For the continuous preparation of uniform-size polymer nanofibers, the through-hole density in the spinneret was important. When anodic porous alumina in which all the holes were through-holed was used, the polymer solution injected from most of the holes coalesced before solidifying into the nanofiber because it was difficult for the coagulating solution to reach the center part of the spinneret. However, the alumina membrane with selective through-holes allowed the formation of polymer nanofibers with a uniform diameter from all the holes in the spinneret. This means that the coagulating solution could be supplied effectively to the center of the alumina spinneret with a controlled through-hole density. The diameter of obtained polymer nanofibers could be controlled by changing the hole diameter of anodic porous alumina spinneret.

The process described here allows the high-throughput preparation of fine polymer nanofibers with controlled diameters.