Medium-strength 6061 aluminum alloy is a suitable material for general-purpose structural use because of a good corrosion resistance and a good toughness., Table 2, Table 3 The effect of hot forging conditions on the microstructure in a 6061 aluminum alloy has been closely investigated, and the mechanism for the microstructure formation has been discussed. Specimens of 6061 aluminum alloy ingots shown in Table 1 were hot-forged at various temperatures and strain rates as shown in Table 2, and then T6-tempered. Microstructures of as-forged as well as T6-tempered were characterized mainly with EBSD and TEM.

Table 3 shows the mechanical properties of the T6-tempered samples. Non-recrystallized structures were formed by hot forging at all the Zener Hollomon parameters (Z parameters) from 1.1![]() 106s-1 to 1.4

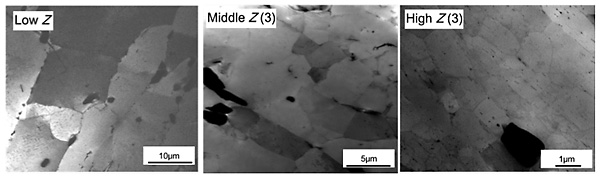

106s-1 to 1.4![]() 1012s-1, which consisted of grains surrounded by high and low angle grain boundaries (Fig. 1). The microstructure became refined with increasing Z (Figs. 2 and 3). This refinement was attributable to grain subdivision mechanism that occurred during hot forging. Because of finer microstructure prior of solution treatment and non-occurrence of recrystallization, the microstructure of middle Z was finer than that of low Z. In the low Z and the middle Z conditions, these microstructures were thermally stable, did not change even after high temperature solution heat treatment. In contrast, in the high Z condition, a small number of nuclei were considered to form in the deformation microstructure because of high density of dislocations, resulting in coarse recrystallized microstructure.

1012s-1, which consisted of grains surrounded by high and low angle grain boundaries (Fig. 1). The microstructure became refined with increasing Z (Figs. 2 and 3). This refinement was attributable to grain subdivision mechanism that occurred during hot forging. Because of finer microstructure prior of solution treatment and non-occurrence of recrystallization, the microstructure of middle Z was finer than that of low Z. In the low Z and the middle Z conditions, these microstructures were thermally stable, did not change even after high temperature solution heat treatment. In contrast, in the high Z condition, a small number of nuclei were considered to form in the deformation microstructure because of high density of dislocations, resulting in coarse recrystallized microstructure.