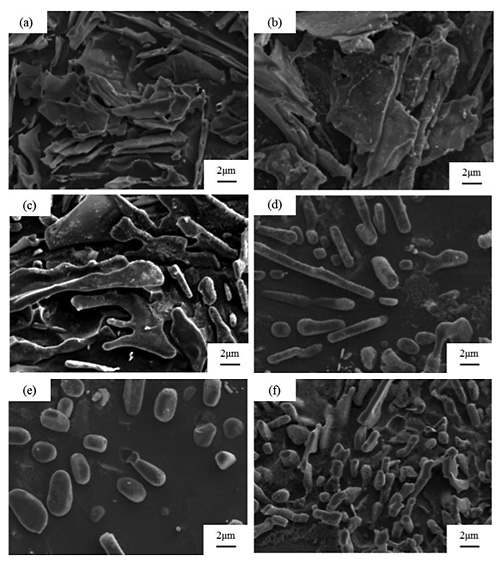

The morphology of eutectic Si particles in Al-11%Si-2.5%Cu alloy was changed by heat treatment and rapid solidification in the aim to study the influence of the morphology of eutectic Si particles on bendability. Figure 1 shows SEM micrographs of eutectic Si particles in the mid-central region of the permanent mold cast specimens (Fig. 1(a)-(e)) and the twin-roll cast product (Fig. 1(f)). Eutectic Si particles were plate-like in the as-cast condition of permanent mold cast specimens (Fig. 1(a)). The rounding of the plate edges was observed by short heat treatment (500![]() -0h), as shown in Fig. 1(c). The morphology of the eutectic Si particles became rod-like and globular with increasing heat treatment time (Fig. 1(d), (e)). On the other hand, in a twin-roll cast product, the eutectic Si particles were rod-like in the as-cast condition (Fig. 1(f)). Table 1 shows average diameter and aspect ratio of the eutectic Si particles in each specimen. The aspect ratio of the eutectic Si particles in the twin-roll cast product was almost the same as that obtained by heat treatment time of 0.5h, and the average eutectic Si particle diameter in the twin-roll cast product was the smallest in all specimens. The specimens for bending test were prepared by means of grinding so that the bending surface was the mid-central region of the cast products. As a result of bending tests, the permanent mold cast specimen (as-cast) was fractured at a bending angle of 45

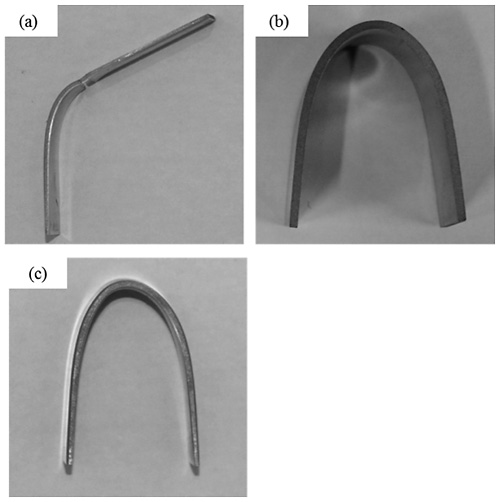

-0h), as shown in Fig. 1(c). The morphology of the eutectic Si particles became rod-like and globular with increasing heat treatment time (Fig. 1(d), (e)). On the other hand, in a twin-roll cast product, the eutectic Si particles were rod-like in the as-cast condition (Fig. 1(f)). Table 1 shows average diameter and aspect ratio of the eutectic Si particles in each specimen. The aspect ratio of the eutectic Si particles in the twin-roll cast product was almost the same as that obtained by heat treatment time of 0.5h, and the average eutectic Si particle diameter in the twin-roll cast product was the smallest in all specimens. The specimens for bending test were prepared by means of grinding so that the bending surface was the mid-central region of the cast products. As a result of bending tests, the permanent mold cast specimen (as-cast) was fractured at a bending angle of 45![]() , as shown in Fig. 2(a). On the other hand, the heat treated (500°

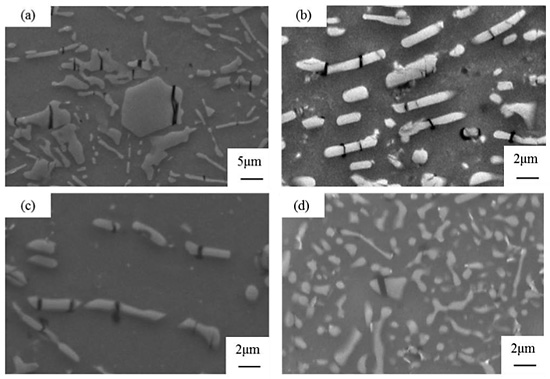

, as shown in Fig. 2(a). On the other hand, the heat treated (500°![]() -0h) and twin-roll cast specimens could be bent to a bending angle of 180° (Fig. 2(b), (c)). Broken eutectic Si particles were observed near the bending surface, as shown in Fig. 3. Table 2 shows the average diameter and aspect ratio of the broken eutectic Si particles in each specimen after bending test. These results revealed that the large eutectic Si particles having large aspect ratio had broken preferentially. Because the eutectic Si particles in the twin-roll cast product were small and rod-like even in the as-cast condition by rapid solidification, the bendability could be improved by decrease of the broken eutectic Si particles, as well as the heat treated specimens. When the chill layer of the twin-roll cast product was chosen as the bending surface, the specimen was fractured only at the bending angle of 80

-0h) and twin-roll cast specimens could be bent to a bending angle of 180° (Fig. 2(b), (c)). Broken eutectic Si particles were observed near the bending surface, as shown in Fig. 3. Table 2 shows the average diameter and aspect ratio of the broken eutectic Si particles in each specimen after bending test. These results revealed that the large eutectic Si particles having large aspect ratio had broken preferentially. Because the eutectic Si particles in the twin-roll cast product were small and rod-like even in the as-cast condition by rapid solidification, the bendability could be improved by decrease of the broken eutectic Si particles, as well as the heat treated specimens. When the chill layer of the twin-roll cast product was chosen as the bending surface, the specimen was fractured only at the bending angle of 80![]() . This is considered due to the difficulty of deforming the matrix by the excess Cu solution. The twin-roll cast specimens of Al-11%Si alloy could be bent to a bending angle of 180

. This is considered due to the difficulty of deforming the matrix by the excess Cu solution. The twin-roll cast specimens of Al-11%Si alloy could be bent to a bending angle of 180![]() , although the bending surface was the chill layer.

, although the bending surface was the chill layer.

[Published in Journal of Japan Foundry Engineering Society, Vol. 85, No. 7 (2013) pp. 407-413]

|

|

|

| Fig. 1 SEM micrographs of eutectic Si particles in Al-Si-Cu alloy. Mid-central region of permanent mold cast products: (a) as-cast, (b) 400 |

|

Table 1 Average diameter and aspect ratio of eutectic Si particles in each specimen. |

|

|

|

|

|

| Fig. 2 Appearances of specimens after bending test. Permanent mold cast products: (a) as-cast, (b) 500 |

|

|

|

| Fig. 3 SEM micrographs of broken eutectic Si particles. Permanent mold cast products: (a) 500 |

|

Table 2 Average diameter and aspect ratio of broken eutectic Si particles in each specimen after bending test. |

|

|