A strip of Al-2mass% Si alloy, which has a wide freezing temperature range, was fabricated using a high-speed twin-roll caster. In this study, a large feeding nozzle was used to obtain a high melt pool level during the strip casting. Formation of solidification structure and several casting defects such as inverse segregation and internal cracking were studied, and the following conclusions were obtained.

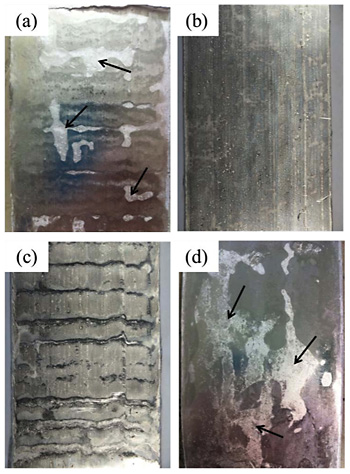

(1) Un-stable contact condition between the solidifying shell and the roll surface was considered to result in several kinds of surface defects such as the ripple mark, "un-shiny" region and the compositional inverse segregation as well as in-homogeneous grain structure, as shown in Fig. 1.

(2) As the melt pool level in the nozzle increased, the strip thickness increased, as shown in Fig. 2, the strip thickness increased by improved contact condition between the solidifying shell and the roll surface and the overall contact condition became stable.

(3) By constructing and keeping the high melt pool level in the feeding nozzle, the formation of the surface defects was prevented effectively.

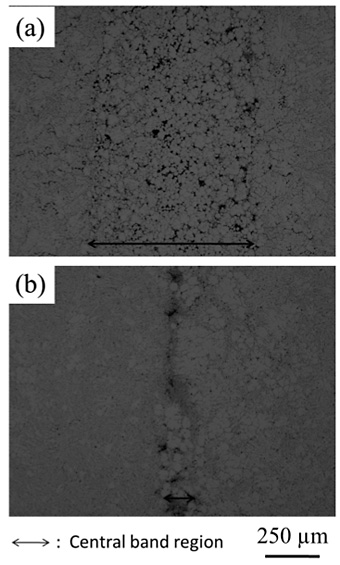

(4) A large-scale internal cracking was observed in the central band region consisting of fine globular grains. The cracking was assumed to relate with the residual liquid in the central band and the roll separating force, as shown in Fig. 3.

(5) It was considered that the roll separating force caused the shear localization in the central band region and promoted a formation of continuous liquid film in the shear localized region, and consequently, the connected shrinkage cavity in the liquid film resulted in the continuous internal cracking when the strip went through the roll nip.

2 mass% Si Alloy Strip

2 mass% Si Alloy Strip