Friction stir welding (FSW) has been applied to lap joint of 5052 aluminum foils of 0.1mm thick. The FSW equipment for foils was successfully designed with a high speed air spindle for tool rotation in consideration of heat input per unit length of welding.

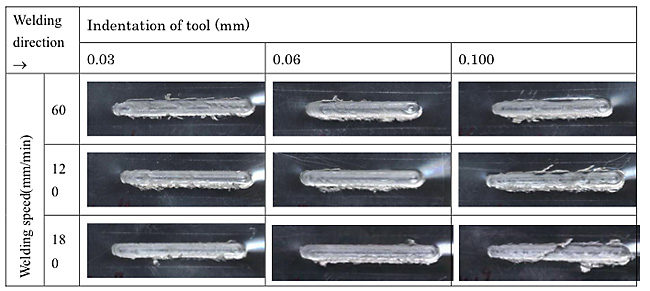

The bead width was extended with increase of the indentation of the tool having a top radius of 16.3mm in FSW with a rotation speed of 120000rpm. More flash was generated as the indentation of the tool increased or the welding speed decreased in FSW with R16.3mm tool. The flash formation was concentrated in retreating side of FSW (Fig. 1).

Figure 2 displays relation between bonding strength PBond and welding speed VW in various indentations of the tool. The bonding strength remarkably depended on the welding speed and seemed to have an optimum speed. The smaller indentation led to the higher strength at the optimum speed. The maximum bonding strength was obtained in FSW with R16.3mm tool, a rotation speed of 90000rpm, an indentation of 0.03mm and a welding speed of 180mm/min. Three types of cylinder shape tools with top radius R of 16.3, 4.1mm and no, and besides a cone shape one were used for FSW. Comparison of the four types of tool shape suggested that R16.3mm tool would be the most appropriate for lap FSW of 5052 aluminum alloy foils.