Ultrasonic vibration was applied during solidification of the AC4CH alloy (Al-7.00Si-0.38Mg, in mass%) to investigate the grain refining effect, reduction of segregation and elimination of porosity. Table 1 shows chemical composition of the AC4CH alloy. Figure 1 shows experimental apparatus of ultrasonic vibration. And, Fig. 2 shows position of horn.

Ultrasonic vibration with the frequency and amplitude of 19kHz and 12![]() m was used. The horn made of a SIALON (shape: straight type, diameter: 20 mm, length: 280 mm) was inserted into the liquid AC4CH alloy. The T6 treatment was given to the specimen after solidification.

m was used. The horn made of a SIALON (shape: straight type, diameter: 20 mm, length: 280 mm) was inserted into the liquid AC4CH alloy. The T6 treatment was given to the specimen after solidification.

Tensile tests were performed on an Instron tensile testing machine at a crosshead speed of 1 mm/min (strain rate 2.8![]() 10-4 /s), using JIS-4 type tensile specimens. Figure 3 shows shape of the JIS-4 type specimen. Hardness was measured with dynamic ultra micro-Vickers hardness tester.

10-4 /s), using JIS-4 type tensile specimens. Figure 3 shows shape of the JIS-4 type specimen. Hardness was measured with dynamic ultra micro-Vickers hardness tester.

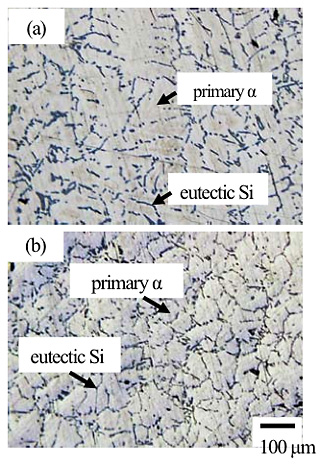

Figure 4 shows microstructure of AC4CH by ultrasonic vibration ((a) without ultrasonic vibration, (b) with ultrasonic vibration). The mean grain diameter of the primary ![]() -Al phase produced with ultrasonic vibration in a CO2 sand mold was smaller than that without ultrasonic vibration. Figure 5 shows variations in (a) tensile strength (TS), (b) yield stress (YS), (c) total elongation (TEl) and (d) Vickers hardness (HV) using ultrasonic vibration (F specimen). And, Fig. 6 shows variations in (a) tensile strength (TS), (b) yield stress (YS), (c) total elongation (TEl) and (d) Vickers hardness (HV) using ultrasonic vibration after T6. The tensile strength (TS) and Vickers hardness (HV) of the specimen produced with ultrasonic vibration were higher than those without ultrasonic vibration. On the other hand, total elongation (TEl) was almost constant.

-Al phase produced with ultrasonic vibration in a CO2 sand mold was smaller than that without ultrasonic vibration. Figure 5 shows variations in (a) tensile strength (TS), (b) yield stress (YS), (c) total elongation (TEl) and (d) Vickers hardness (HV) using ultrasonic vibration (F specimen). And, Fig. 6 shows variations in (a) tensile strength (TS), (b) yield stress (YS), (c) total elongation (TEl) and (d) Vickers hardness (HV) using ultrasonic vibration after T6. The tensile strength (TS) and Vickers hardness (HV) of the specimen produced with ultrasonic vibration were higher than those without ultrasonic vibration. On the other hand, total elongation (TEl) was almost constant.

Figure 7 shows strength-ductility balance (TS![]() TEl) ((a) F specimen, (b) T6 specimen). It is found that the ultrasonic vibration contributes to the improvement of the strength-ductility balance (TS

TEl) ((a) F specimen, (b) T6 specimen). It is found that the ultrasonic vibration contributes to the improvement of the strength-ductility balance (TS![]() TEl).

TEl).