Preparation of small particles with controlled shapes and sizes have attracted considerable interest due to its applicability to the various fields such as catalysts, sensors, and optical devices so on. A large number of methods have been reported for the preparation of shape- and size-controlled particles. Among them, template processes, in which the porous materials with appropriate pores are used as a starting structure, is promising for the preparation of shape- and size-controlled small particles. In this process, the particles are formed in the pores of starting materials, and subsequent dissolution of template generated isolated small particles. However, in the template process, the throughput of the preparation of particles is low because the use of the starting material is restricted to be single-round. Differently to the template process, the nanoimprinting process, in which the fine structures are prepared by pressing the mold on the substrates, allows the repeated use of the mold, and can accomplish the high throughput yield of preparation. If the nanoimprinting process can be applied to the formation of small particles, accomplishment of the high throughput formation of small particles can be expected. However, until now there has been no report on the fabrication of small particles based on the nanoimprinting process. In the present work, we describe the process for the preparation of polymer and SiO2 small particles of submicron to nanometer scale based on the nanoimprinting using anodic porous alumina mold.

Ideally ordered anodic porous alumina was used as a mold for the fabrication of uniform-sized and -shaped projections by nanoimprinting. The anodization was carried out using phosphoric acid or oxalic acid under a constant anodization voltage. The depth of holes was controlled by the anodization time, and the diameter of holes was adjusted by postetching treatment using phosphoric acid solution. For the fabrication of polymer projection arrays by a nanoimprinting, commercially available photocurable monomer (PAK-02, Toyo Gosei Co.) was used. The uniform-sized projections were formed on a polyethylene terephthalate (PET) sheet by nanoimprinting using anodic porous alumina as a mold. To separate each projection from the substrate, a sacrificial layer was formed on the array projecting structures using a masking agent containing butadiene rubber (Sunecon, Taiyo Chemical & Engineering Co.). The sacrificial layer together with the projection array was mechanically peeled off from the substrate. Then, the sacrificial layer was dissolved selectively in toluene to obtain isolated polymer particles.

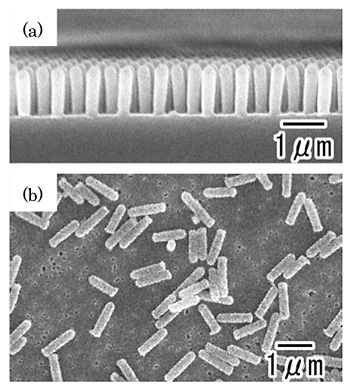

Figure 1a shows a cross-sectional SEM image of a polymer projection array fabricated by nanoimprinting using anodic porous alumina as a mold. From the SEM image in Fig. 1a, it was observed that uniform-sized and -shaped projections were formed on the entire substrate. Figure 1b shows a SEM image of the polymer particles trapped on the filter membrane. As shown in Fig. 1b, the monodisperse polymer particles were obtained by selective dissolution of the sacrificial layer.

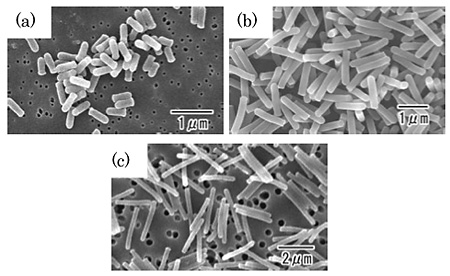

The aspect ratio of the polymer particles could be controlled by adjusting the preparation conditions of the anodic porous alumina molds. Figure 2 shows SEM images of isolated polymer particles obtained by nanoimprinting using anodic porous alumina molds with different hole depths. For these samples, the period and diameter of the holes in the anodic porous alumina molds were adjusted to 500 and 250 nm, respectively, and the depth of holes in the molds was varied from 750 to 2500 nm by changing the anodization time. From the SEM observation, the aspect ratios of the obtained polymer particles were estimated to be 3, 5, and 10, respectively. The sizes of the obtained particles were in good agreement with those of the holes in the anodic porous alumina molds.

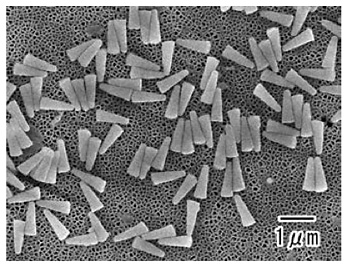

In addition to polymers, the present process can be applied for the preparation of monodisperse particles of inorganic materials. Figure 3 shows a SEM image of SiO2 particles obtained by nanoimprinting using a spin-on-glass solution. An anodic porous alumina mold with tapered holes was used for the nanoimprinting to improve the removal of the SiO2 layer from the mold. From the SEM image in Fig. 3, it was observed that the cone-shaped monodisperse SiO2 particles were trapped on the filter membrane. This means that the present process allows the preparation of monodisperse particles of various materials by changing the material used for nanoimprinting.