Plastic deformation of magnesium alloy is limited because of its hcp structure. Though the grain refined magnesium alloy exhibits superplastic deformation at elevated temperature, the strength decreases due to induced cavitation. This study focusses on developing the random texture of magnesium alloy and causes relatively high plastic deformation even at room temperature.

Commercial cast AZ91 magnesium alloy ingot was used as a starting material. Schematic illustration of the ADB process is shown in Fig. 1. Four sheets were surface treated by a stainless steel wire brush. The stacked sheets were uniaxially hot pressed to 2 mm height under constant load of 15 ton for 1 h. The temperature of these sheets and the pressing jigs was maintained at 673 K. A diffusion bonded sheet was cut to 4 square plates and they were hot pressed again after the same surface treatment.

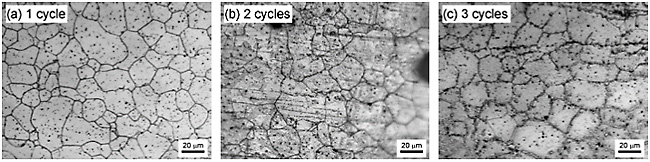

Optical microstructures of AZ91 alloy after 1, 2 and 3 ADB cycles are shown in Fig. 2. The sheets were consists of equiaxial crystal grains. Average grain sizes of 1, 2 and 3 ADB cycles were about 20 ![]() m. The specimen after 0 ADB cycle, as received, has almost random orientation. Diffraction intensity from {0002} basal plane of HCP structure increased with increasing the ADB cycle number [Fig. 3].

m. The specimen after 0 ADB cycle, as received, has almost random orientation. Diffraction intensity from {0002} basal plane of HCP structure increased with increasing the ADB cycle number [Fig. 3].

Tensile stress-strain curves of AZ91 alloy specimens after 0, 1, 2 and 3 ADB cycles were shown in Fig. 4. ADB process was effective to increase both tensile strength and elongation. In Fig. 5, the tensile strength and the elongation to fracture were plotted as a function of ADB cycle number. Tensile strength increased with increasing the ADB cycle number. The AZ91 magnesium alloy after 1 ADB cycle has 25% elongation to fracture which is extremely high compared to conventional AZ91 alloy.

Relationship between tensile strength and elongation is plotted in Fig. 6. The present AZ91 magnesium alloy sheets have higher elongation to fracture than previous AZ91 alloys. Tensile strength of the present AZ91 alloy is the same as that of previous alloys.

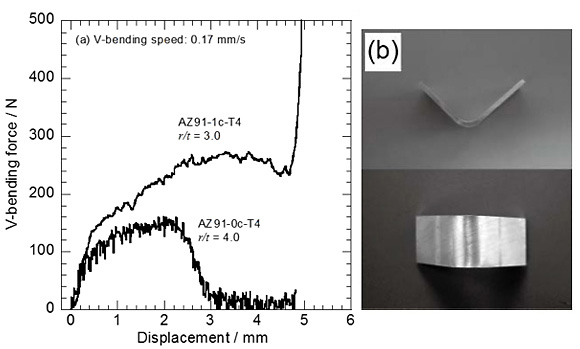

The result of 90° V-bending test at room temperature is shown in Fig. 7. This result indicates that the AZ91 magnesium alloy sheet produced through the ADB processing has a potential of multiaxial plastic deformation. Enhanced plastic deformation in this study is not caused by grain boundary sliding but by random texture development.