A lot of screws and bolts are used as fasteners in the machine element. It leads to lightening by making these with magnesium alloys, and it is possible to contribute to the problem of global environment concerns and energy conservation. In this study, the evaluation of the thread rolling workability at room temperature of magnesium alloy screw of M8 was examined.

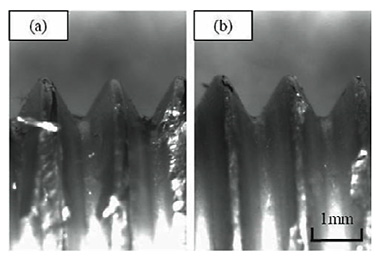

The surface externals appearance of the sample that actually processes the room temperature form rolling to Fig.1 is shown. Fig.1 (a) is the sample without giving the torsion working and anneal for 3.6ks at 673K. It was seen a great many rolling defects such as peeling and cracking of the thread. On the other hand, Fig.1 (b) is the sample treated annealing process for 3.6ks at 673K after torsion working of 1080 degrees, had cracking and peeling of the tip of the screw thread is less than Fig.1 (a). Thus, it was shown that thread rolling workability at the room temperature is improved by the torsion working. However, the forming of the thread has not been solved yet complete.

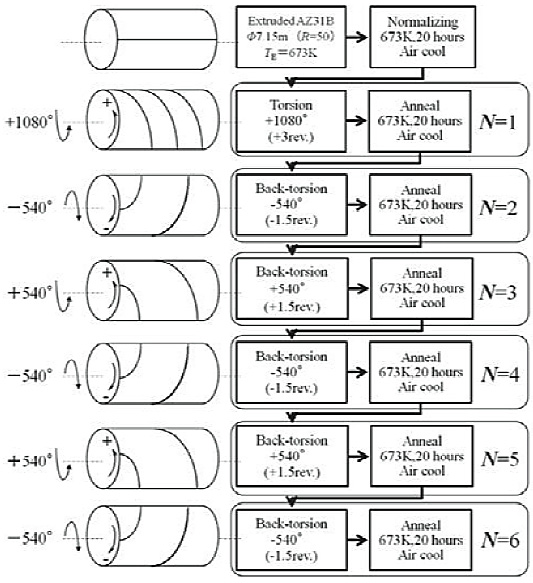

The experimental flow chart of the back-torsion working is shown in Fig.2. First of all, the extruded AZ31B was done normalizing for 72ks at 673K. Afterward, the torsion working of 1080 degrees was added in the direction of the plus, and annealing was treated for 3.6ks at 673K. In addition, the torsion working of the reverse-rotation is done to the previous process, and annealing. This process was repeated two or more times, and it was defined as back-torsion working. The torsion working angle since the second times was set into 540 degrees. In the final process, the torsion working was done until breaking. And, the number of torsion working was assumed to be N.

It processed until breaking when the number of torsion working was N. Then, the relation between the breaking shear strain and the torsion angle is shown in Fig.3. The breaking shear strain increased as N increases. For this reason, the improvement of the workability is suggested by giving the back-torsion working and annealing.

The thread rolling on room temperature result of the back-torsion samples are shown in Fig.4. Fig.4 (a) is a sample that worked thread rolling after torsion working and annealing. Fig.4 (b) is sample that treated annealing after breaking by torsion working of the reverse-rotation by the second processing. Fig.4 (c) is sample that is back torsion working into -540 degrees by the second processing, and broken by torsion working of the normal rotation by the third processing. Hereafter, Fig.4 (d)-(f) is a sample to have given breaking the back torsion working by from four to six times. When Fig.4 (d) and (f) are seen, it is understood that the thread rolling workability at room temperature of the sample is remarkably bad. The torsion working in the final process is the reverse-rotation, in a word, it is understood that thread rolling workability decreases when N is an even number. In addition, when Fig.4 (a), (c) and (e) are compared, samples worked back torsion are less peeling and cracking of the screw thread than only torsion working sample. It is understood that the thread rolling workability improves when there are much N, because peeling and cracking decreased. From these, improving of thread rolling workability became clear, when the back torsion working in the final process is normal rotation, in a word, when N is an add number.

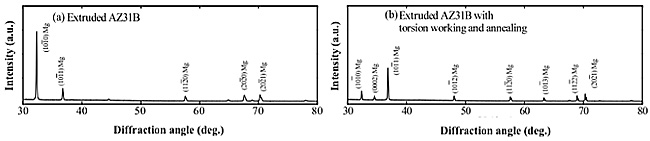

The X-ray diffraction result of extrusion material and torsion working material of AZ31B is shown in Fig.5. In any case, a vertical section was identified in the direction of the extrusion. The diffraction intensity in (1010) face has risen remarkably in the extrusion material. However, the diffraction intensity in (1010) face decreases by giving the torsion working and the annealing, and the diffraction intensity such as (1010), (0002), (1012) and (1013) faces increases. It is suggested that the crystal orientation anisotropy of the extruded material is eased by giving torsion working.